Recent advancements in Air Handling Unit (AHU) technology, highlighting improvements in energy efficiency, air quality, filtration, and smart controls. Modern AHUs use multi-stage filters, advanced heat recovery, variable-speed drives, and modular designs for better performance and lower energy use. Smart automation and predictive maintenance enhance reliability, while improved materials and acoustic features boost comfort and durability. These upgrades make AHUs more effective for ventilation and indoor climate control.

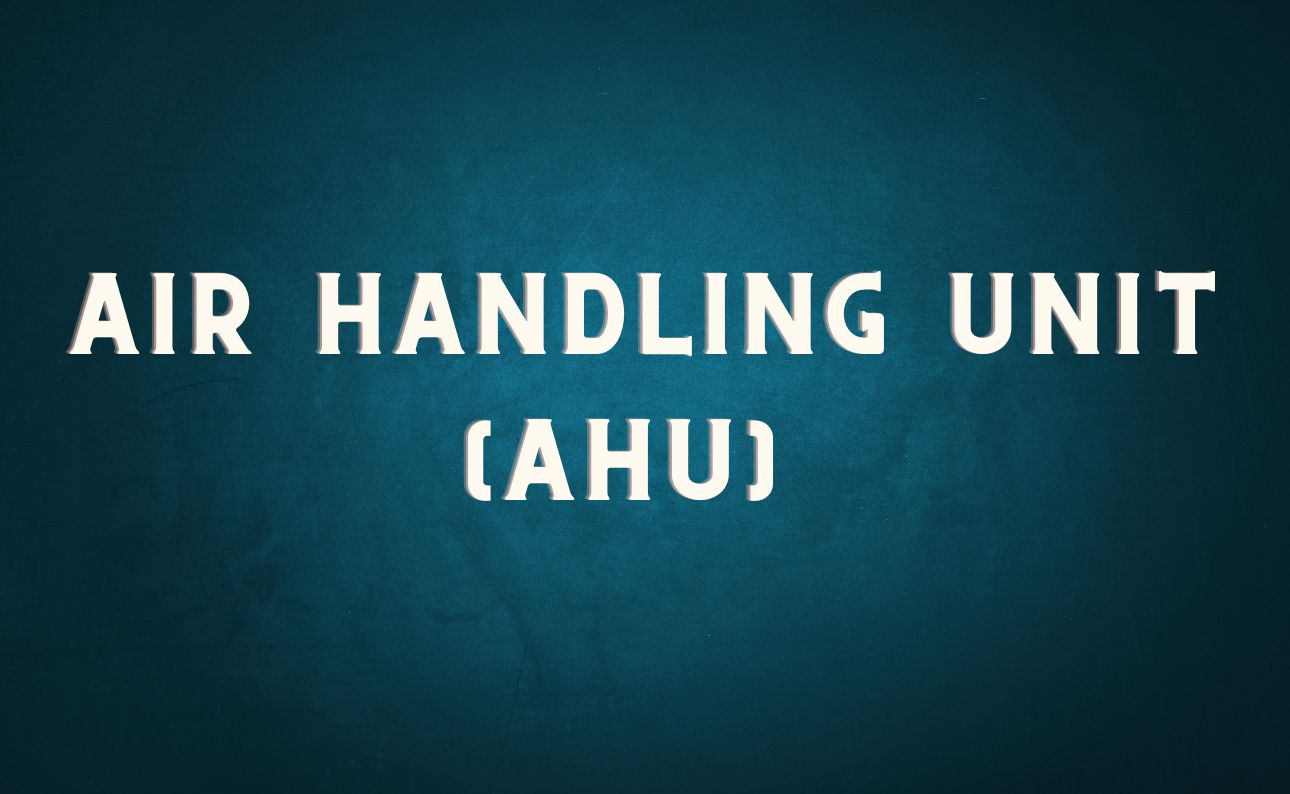

The Air Handling System (AHU) is the Heart of a Heating, Ventilating and Air Conditioning System in air coolers. Air Handling Unit takes fresh air from outside and conditions it before it is pumped into rooms through ducts.

An air handling unit is a vital component of HVAC system responsible for circulating and conditioning the air within a building. This arrangement consists of various components such as fans, filters, coils, dampers, and controls. These parts work together to make sure the air is circulated properly, the temperature is controlled, and the air quality is maintained at a good level. For a long time, conventional Air Handling Units (AHUs) have been employed. However, recent progress has resulted in notable enhancements to their performance and effectiveness.

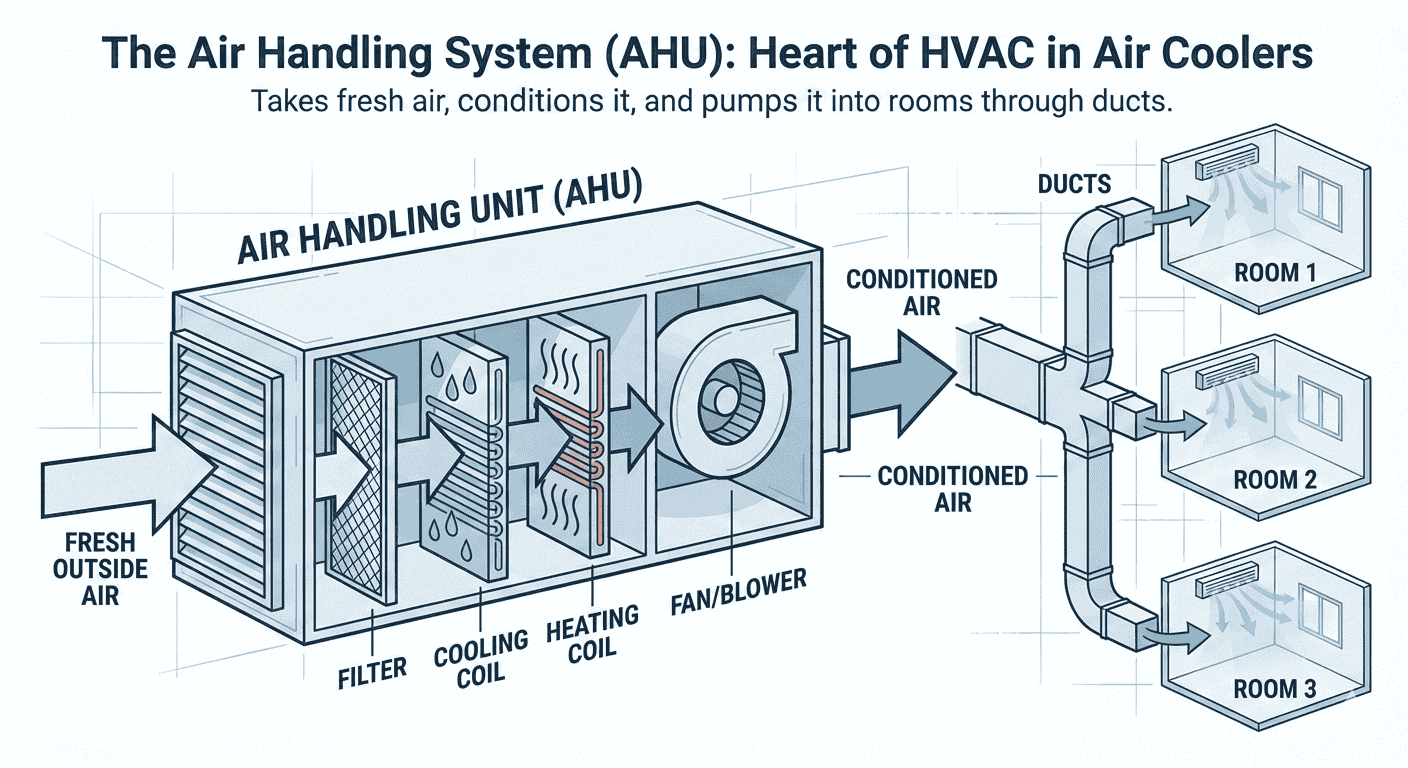

What materials and structural features are essential for a modern AHU casing’s longevity and performance?

Modern AHUs utilize double-skin panel construction with high-density polyurethane (PU) foam insulation between layers of corrosion-resistant material (e.g., pre-painted galvanized iron, or GI, and sometimes stainless steel for hygiene-critical applications). This structural integrity is measured by casing deflection (EN 1886 standard), which ensures minimal air leakage (critical for efficiency) and thermal bridging. Features like a thermal break profile prevent condensation on the exterior surface by isolating the inner and outer casings.

Why is the AHU’s acoustic performance a major commercial selling point for offices and hotels?

In premium commercial environments, noise reduction is directly tied to occupant comfort, health, and productivity. Modern AHUs minimize noise (a crucial compliance factor) through several technologies: Double-skin panel construction utilizing dense, inert acoustic insulation (e.g., mineral wool or PU foam) and Sound Attenuators (silencers) strategically placed at the fan inlet/outlet. The use of Plug Fans (centrifugal fans without a scroll) minimizes turbulence noise and allows for simpler integration into the casing. Low noise levels are vital for achieving high Noise Reduction Coefficient (NRC) standards required for a quality commercial lease.

Read Our Article: Double Skin Air Handling Units: Advantages in Industrial Cooling

Table of Contents

Energy Efficiency Improvements with AHU

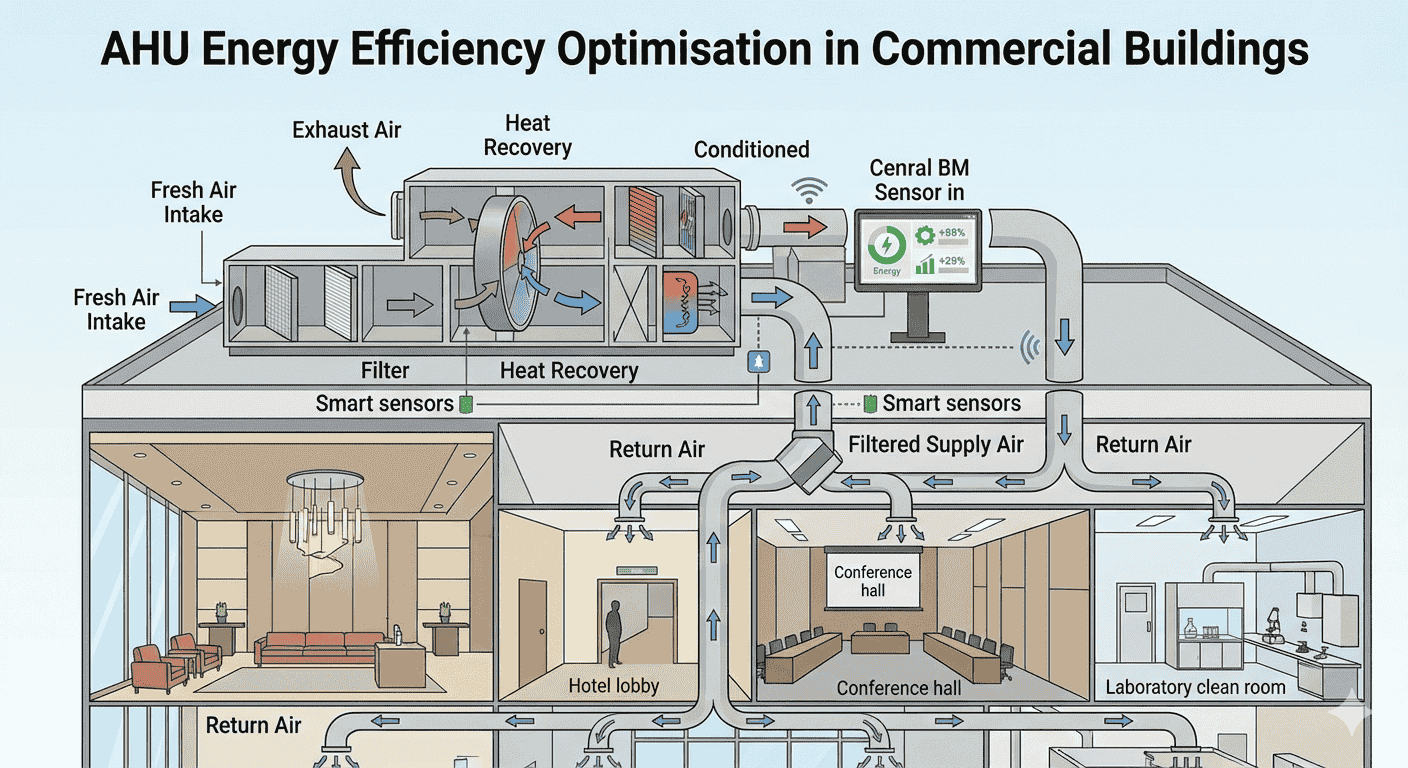

AHUs are a vital component of commercial ventilation and air-conditioning system. They manage ventilation by collecting outdoor and room (air already present in the building) air, separating them from waste air, filtering it, adjusting temperature and humidity and then distributing a fresh supply of conditioned air throughout a building using ductwork.

They are particularly useful in large spaces that have limited natural ventilation, such as hotel dining rooms and conference or convention centres, where there are many simultaneous visitors. They also help to maintain ‘clean rooms’ such as laboratories and operating theatres by removing contaminated air and replacing it with fresh air.

Beyond basic air filters, what are the current global standards for AHU filtration and why is multi-stage filtering critical?

Modern AHUs use multi-stage filtration adhering to ISO 16890 (which replaced the old EN 779 standard) or ASHRAE 52.2 (MERV rating). A typical setup involves: Pre-filters (ISO Coarse or MERV 8) to capture large particulates, Fine Filters (ePM10 or MERV 11-13) for PM10/PM2.5, and often HEPA filters (H13/H14) or ULPA filters for highly sensitive areas (like operating theaters or clean rooms, as mentioned). Multi-stage filtering is crucial because pre-filters protect the expensive high-efficiency filters from large debris, significantly extending their lifespan and maintaining low-pressure drop across the system.

Advances in energy efficiency mean that today’s air handling units are now designed to consume less energy. They do this by combining a range of technologies in an efficient package, including heat recovery and advanced control systems.

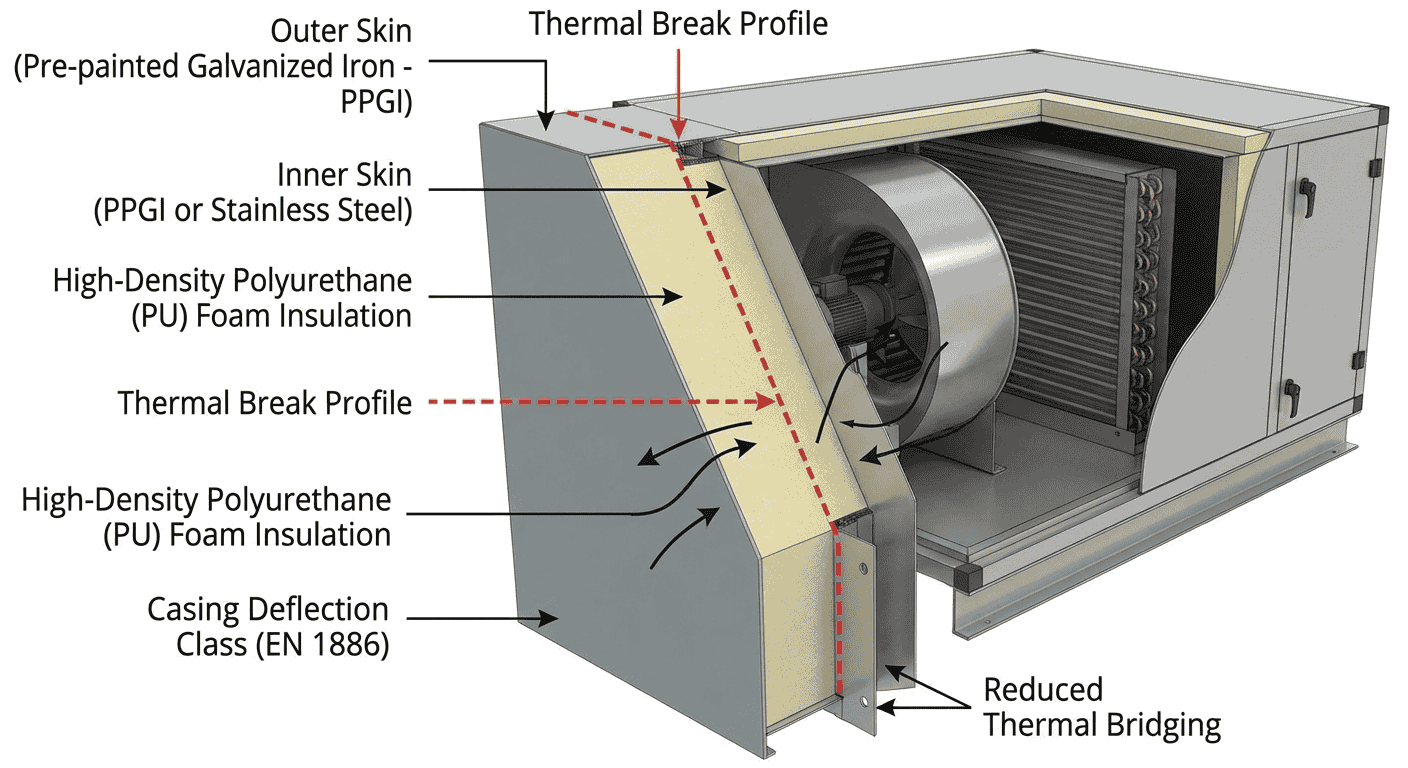

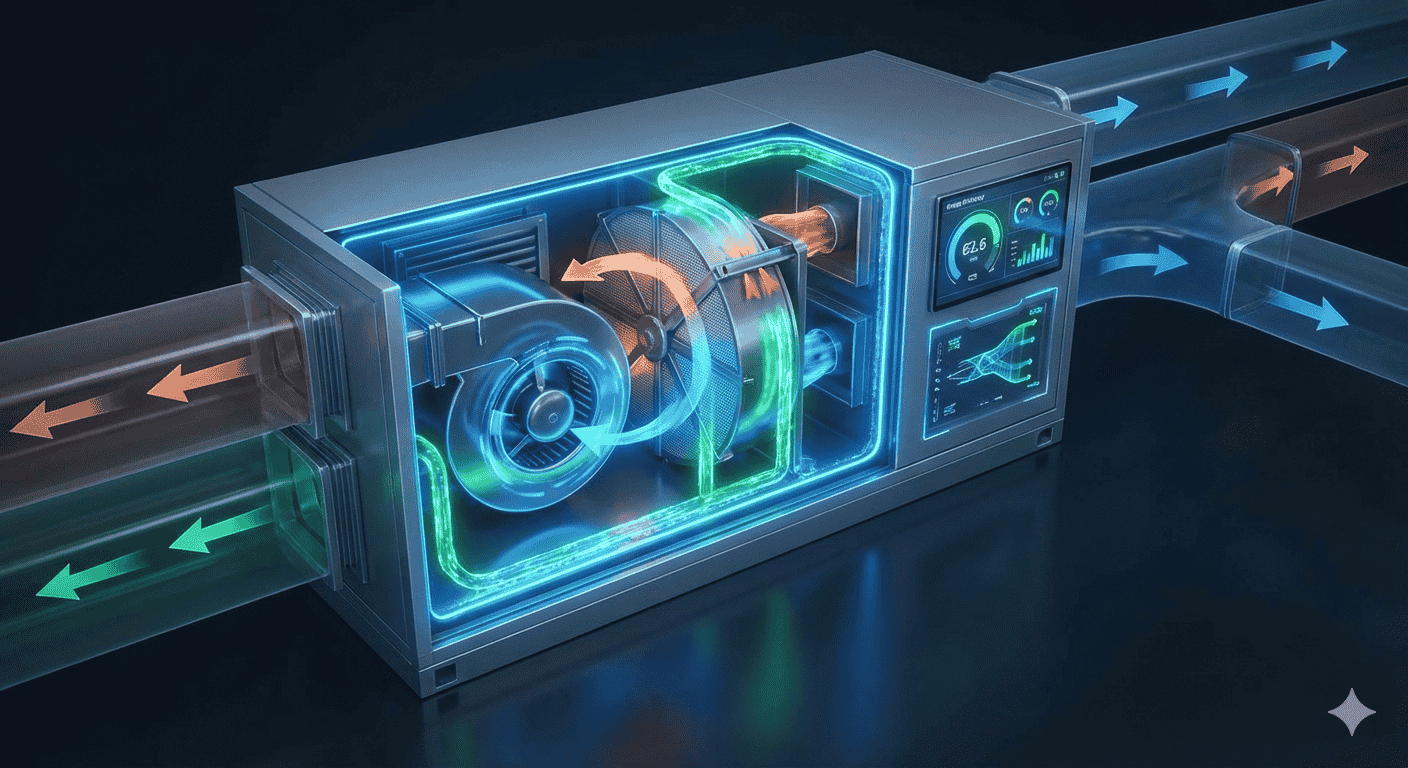

What specific types of heat recovery mechanisms are currently integrated into high-efficiency AHUs?

High-efficiency AHUs rely on various Air-to-Air Heat Recovery devices to pre-condition the fresh incoming air using the energy from the exhausted room air, significantly reducing the coil load. Key types include: 1. Run-around Coils: Uses a liquid loop to transfer sensible heat between two distant air streams. 2. Plate Heat Exchangers (or Cross-Plate Exchangers): Transfers both sensible and latent heat with no mixing of air streams, offering high energy recovery effectiveness (ERE) up to 70%. 3. Rotary Heat Exchangers (Thermal Wheels): A spinning wheel coated with an adsorbent material transfers both sensible heat and moisture (latent heat) between the air streams, achieving up to 80% ERE, making it highly effective for humidity control.

Variable-speed drives (VSDs) are now integrated into AHUs, allowing fans to operate at varying speeds based on demand, resulting in significant energy savings. Additionally, advanced control algorithms and sensors enable precise control over temperature and airflow, reducing energy wastage.

Read Our Article: The Role of AHU & Double Skin Air Handling Units in Venti Cooling for Industrial Applications

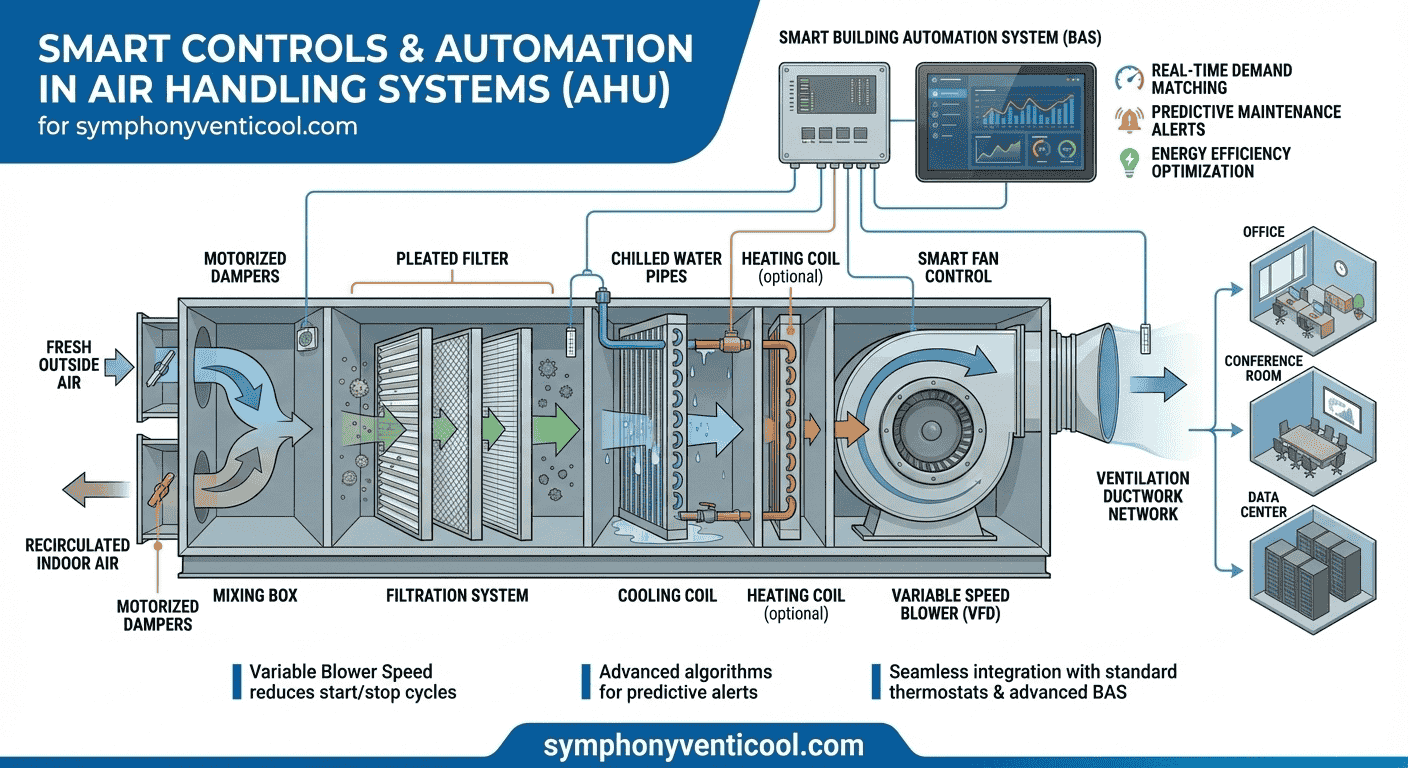

Air Handling Systems – Smart Controls and Automation

Air handlers are massive indoor units of HVAC equipment that condition and circulate a building’s interior air through ductwork. They can either draw in fresh air from outside, or recirculate and condition existing indoor air to filter, cool, and heat it.

The air handlers fan blows air through its internal system of a mixing box, filters and cooling coil before it is blown into the ventilation ductwork network. They can be sized to meet different energy efficiency and comfort goals.

The most advanced air handling systems feature variable blower speeds to match demand and reduce starting and stopping. These units can be controlled by a standard on/off thermostat or by an advanced building automation system. Moreover, advanced algorithms enable predictive maintenance, alerting facility managers about potential issues before they escalate.

Air Handlers in Building Ventilation and Temperature Control

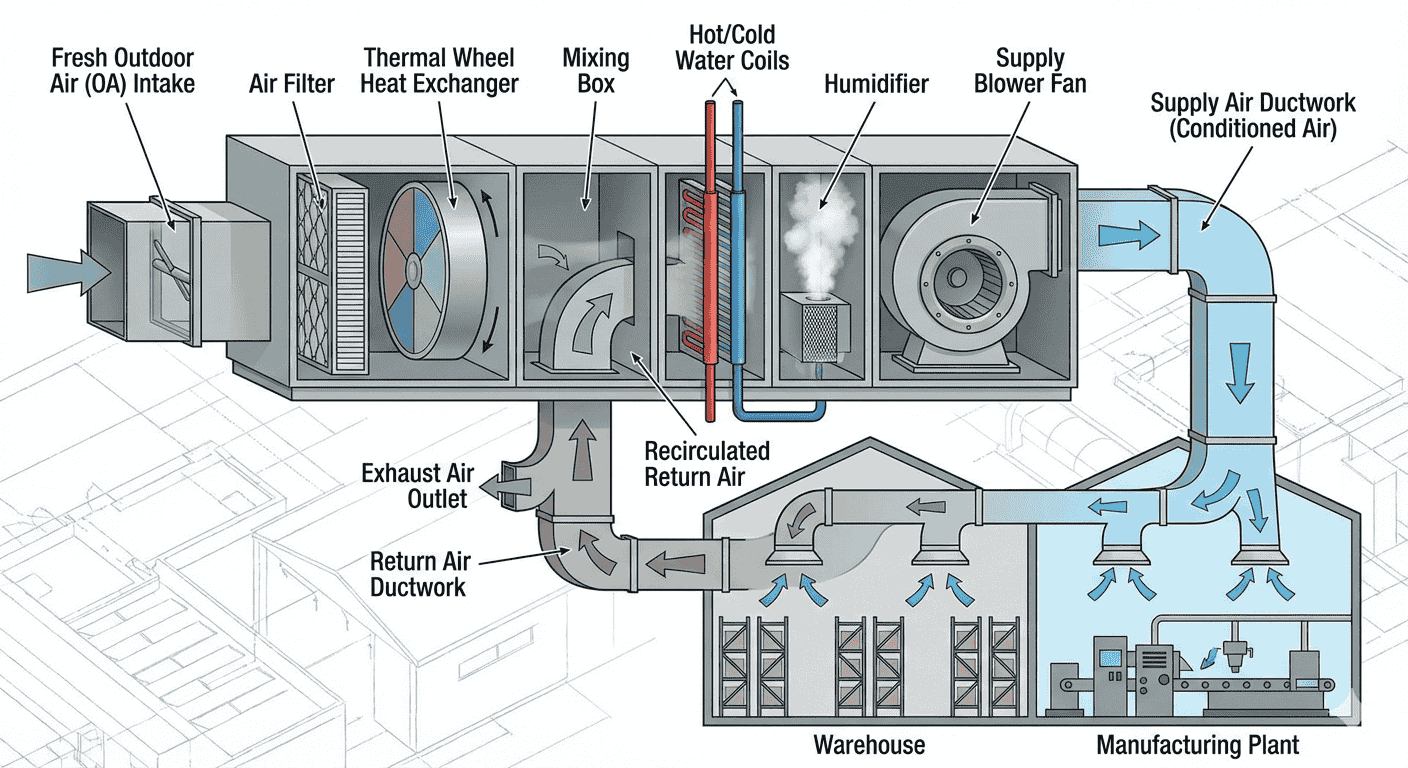

An air handler regulates and circulates as part of a building’s ventilation, heating and cooling system. It’s critical for industrial settings like warehouses and manufacturing plants to keep employees safe and productive.

Fresh, conditioned air is distributed to indoor spaces through ductwork. During times when outdoor air (OA) is not needed for space conditioning, OA is recirculated back to the AHU through return and exhaust ductwork. This air is reconditioned in the mixing box and sent to non-hazardous indoor spaces.

The AHU contains a hot/cold water coil; reheat coil, air filter, humidifier and blower fans. The mixing box utilizes a thermal wheel or cross plate heat exchanger to exchange heat between chilled/heated water or refrigerant and OA to adjust the temperature. Labeling HVAC components is an effective method to help facilities personnel identify potential issues and prevent them from occurring. This is especially important for a facility’s most critical systems such as AHUs.

What is the benefit of a modular AHU design, especially for large or complex commercial projects?

Modular design involves manufacturing AHUs in standardized sections (modules) that are assembled on-site. This offers unparalleled flexibility in configuration, allowing engineers to custom-build the AHU sequence (e.g., mixing box, filters, heating/cooling coils, fan section) to precisely fit restricted spaces or specific performance criteria. It significantly reduces installation time and labor costs compared to fully site-built units. This design also simplifies future maintenance and upgrades, as individual sections (like a dehumidifier module or an energy recovery wheel) can be accessed or replaced without dismantling the entire system.

Role of Air Handling Units (AHU) in HVAC Systems Enhancing Comfort and Safety

Air handling systems are at the heart of a heating, ventilating and air conditioning system. They collect and condition air to circulate throughout the building, removing heat, adjusting humidity and ensuring high quality fresh air for the occupants.

AHUs can also help protect people and property in large facilities visited by many people, such as theatres or shopping malls, where the amount of carbon dioxide is strictly controlled. They can do this by filtering the air, ensuring that dangerous viruses, bacteria and odours are excluded.

Advanced technologies and custom features are packed into a streamlined package that’s easy to install and maintain. They combine energy recovery technology with a humidification solution, unit control and dampers that are fully compliant with ERP (Ergonomics of the Working Environment) requirements. The result is an AHU with a high quality air supply, meeting stringent hygiene standards and delivering maximum energy savings.

Air Handling Unit (AHU) Technology Advancements

What is an air handling unit (AHU)?

Air handling unit is a crucial component of HVAC systems that circulates and conditions the air within a building. It consists of fans, filters, coils, dampers, and controls that work together to ensure proper air circulation, temperature control, and air quality maintenance.

How does an air handling system improve energy efficiency?

Advancements in energy efficiency have led to improved performance in air handling systems. They achieve energy savings through technologies such as variable-speed drives (VSDs), which allow fans to operate at varying speeds based on demand. Additionally, advanced control algorithms and sensors enable precise control over temperature and airflow, reducing energy wastage.

What are the benefits of smart controls and automation in air handling units?

Smart controls and automation enhance the functionality of air handling units. They enable variable blower speeds to match demand, reducing starting and stopping cycles. Air handling units can be controlled by standard thermostats or advanced building automation systems. Advanced algorithms also facilitate predictive maintenance, notifying facility managers about potential issues before they escalate.

How do air handlers contribute to building ventilation and temperature control?

Air handlers play a crucial role in regulating and circulating air within a building’s ventilation, heating, and cooling system. They distribute fresh, conditioned air through ductwork and can recirculate and condition existing indoor air. Air handlers contain components such as a hot/cold water coil, air filter, humidifier, and blower fans to adjust the temperature and maintain indoor air quality.

What are some key features to consider when selecting an air handling system?

When selecting an air handling system, key features to consider include energy efficiency ratings, the presence of variable-speed drives, advanced control systems, filtration capabilities, ease of maintenance, and compliance with hygiene standards and regulations.

How does an AHU improve indoor air quality in offices?

- Air Filtration: AHUs use high-efficiency filters (such as MERV 13 or HEPA) to trap dust, allergens, bacteria, and other particulate matter, ensuring clean air circulation in the office.

- Humidity Control: By regulating the humidity levels within a specific range (30-60%), AHUs help prevent the growth of mold and bacteria, maintaining a healthy indoor environment.

- Ventilation: AHUs bring in fresh outdoor air and remove stale indoor air, ensuring proper ventilation and preventing the buildup of CO2, which can cause fatigue and discomfort.

- Airflow Distribution: Proper distribution of conditioned air through ducting helps maintain uniform temperature and airflow, reducing the risk of cold or hot spots, which can affect comfort and productivity.

How to choose the right AHU size?

- Space and Ventilation Needs: The first step is to determine the total air volume required to ensure sufficient ventilation. This is typically measured in cubic feet per minute (CFM).

- Occupancy: A larger space will require a higher CFM to ensure adequate fresh air and air exchange.

- Heat Load Calculation: The AHU size should account for heat generated by lighting, appliances, and the number of people in that location.

- Insulation and Window Quality: Well-insulated walls or those with energy-efficient windows may need smaller AHUs as they retain air better, reducing the load on the system.

- Consult an Expert: It’s advisable to consult with an HVAC professional to perform a Manual J Load Calculation to ensure the correct AHU size is selected.

Compare AHU features for industrial use in India.

- Capacity: Industrial AHUs are generally larger and designed to handle higher airflow (CFM) compared to commercial units. The required capacity depends on the size and function of the industrial facility.

- Customizable Features: Industrial AHUs often come with customizable features like heat recovery systems, humidification, dehumidification, and filtration to meet specific industrial requirements.

- Durability and Corrosion Resistance: Industrial environments in India, especially in coastal or humid areas, require AHUs with corrosion-resistant components, such as galvanized steel or stainless steel housing.

- Energy Efficiency: With rising energy costs, energy-efficient AHUs featuring VFD motors, EC motors, and heat recovery systems are in high demand for industrial facilities.

- Maintenance Access: Industrial AHUs are designed for easy maintenance, with features like easily removable panels and access doors to simplify cleaning and repair processes.

What are the latest AHU technologies used in smart buildings?

- IoT Integration: AHUs are increasingly equipped with IoT sensors to monitor and optimize air quality, temperature, humidity, and energy usage in real-time.

- Smart Control Systems: Integration with Building Management Systems (BMS) allows AHUs to adjust parameters like airflow and temperature based on occupancy, time of day, and ambient weather conditions.

- Energy Recovery Ventilation (ERV): This technology uses an exchange of heat or energy between incoming and outgoing air, reducing the need for additional heating or cooling, optimizing energy use.

- Air Quality Sensors: Modern AHUs are equipped with sensors to detect pollutants, VOCs, and CO2 levels, enabling them to adjust air filtration and ventilation based on the detected air quality.

- Predictive Maintenance: Advanced sensors and AI software predict when parts may need maintenance or replacement, reducing downtime and improving system longevity.

What is an Air Handling Unit room and why is it important in building ventilation?

- Definition: An AHU room is a dedicated space in a building where the air handling unit is installed, typically located on the rooftop, basement, or mechanical floor.

- Importance: The AHU room is critical for housing the unit in a controlled environment, where air temperature, humidity, and cleanliness can be maintained for optimal performance. It also provides easy access for maintenance and repair.

- Proper Setup: Ensuring that the AHU room is properly sealed, insulated, and ventilated is crucial to maintaining efficient airflow and preventing contamination of the air supply.

How to design an AHU room for optimal airflow in commercial buildings?

- Space Considerations: Ensure the room is large enough to accommodate the AHU with adequate clearance for maintenance and airflow. The layout should allow for sufficient space around the unit for easy access and servicing.

- Airflow Pathways: The AHU room should be designed with dedicated intake and exhaust pathways to maintain proper air circulation and prevent air recirculation or contamination.

- Ventilation: Adequate ventilation should be provided in the AHU room to maintain air quality and prevent overheating of the unit. Use louvered doors or vents for proper exhaust.

- Isolation of Noise: AHUs can be noisy, so noise-dampening materials should be used in the room’s design to prevent excessive sound transmission into the building.

Cost estimate for setting up an Air Handler room in a mid-size industrial facility?

- Initial Setup Costs of AHU: The cost can vary widely depending on the size of the AHU, the complexity of the system, and the building layout.

- Factors Affecting Costs:

- Size of AHU: Larger units will incur higher costs due to the need for bigger AHU rooms.

- Customization Requirements: Special features such as heat recovery, air filtration systems, and energy-saving technologies add to the cost.

- Construction and Ventilation: Costs related to the construction of the AHU room, including insulation, noise reduction, and ventilation systems, are additional.

- Ongoing Maintenance Costs: Routine maintenance, including filter replacement, motor servicing, and duct cleaning, adds to the total cost of ownership.

What are the safety standards and regulations for Air Handling Unit rooms in India?

- Building Code Compliance: AHU rooms must comply with the National Building Code of India (NBC) and local municipal codes.

- Fire Safety Standards: The room must be designed with fire safety in mind, including fire-resistant walls, fire exits, and fire suppression systems. AHU rooms should be equipped with smoke detectors and alarms.

- Electrical Safety: AHUs are typically powered by high-voltage electrical systems. Compliance with the Indian Electricity Rules, along with proper earthing, circuit breakers, and isolation switches, is mandatory.

- Ventilation and Air Quality: Proper ventilation and air quality standards must be maintained in the AHU room to prevent overheating, which can reduce the AHU’s lifespan and efficiency.

How to improve energy efficiency of an AHU room in a commercial complex?

- Optimized Equipment: Use high-efficiency AHUs, motors, and energy recovery ventilators (ERVs) to reduce energy consumption.

- Proper Insulation: Insulate the AHU room and ducts to prevent heat loss and reduce the need for additional heating or cooling.

- Maintenance: Regular cleaning of filters, coils, and fans ensures that the AHU operates at peak efficiency.

- Variable Speed Drives (VSD): Installing VSDs on motors ensures that airflow and energy consumption are adjusted according to demand, improving overall efficiency.

- Energy Management System (EMS): An EMS can help monitor and control energy use in the AHU room, providing real-time data to optimize performance.

Conclusion

The advancements in Air Handling System (AHU) technology have revolutionized the field of heating, ventilation, and air conditioning (HVAC) systems. AHUs, often regarded as the heart of such systems, have undergone significant improvements that enhance performance and efficiency. These units are essential for maintaining optimal air quality and comfort in various indoor spaces, especially in large areas with limited natural ventilation.

The integration of the latest technology has led to remarkable progress in AHU design. Energy efficiency has taken center stage, with features such as variable-speed drives, heat recovery mechanisms, and advanced control systems becoming standard components. These innovations enable AHUs to consume less energy while effectively conditioning and distributing fresh air throughout buildings.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.