today’s factories, workers need to have a comfortable and efficient place to work. This is where the Industrial Cooling System with duct for the factory comes in. It’s like a super smart machine that makes hot factory areas much cooler and more comfortable. Let’s explore what these industrial ducting coolers are all about and see how they’re making factories better workplaces.

Table of Contents

Understanding the Need of Factory Cooling System

Factories: The Heartbeat of Production

Factories are the heartbeat of production, often bustling with activity and machinery generating significant heat. As temperatures rise, so do concerns about worker comfort and overall efficiency.

Challenges in Factory Environments

Temperature Regulation: Maintaining optimal temperatures in factory environments is crucial for worker productivity and well-being.

Energy Consumption: Traditional cooling systems can be costly to operate, especially in large factory spaces.

Air Quality: Poor air quality can lead to health issues and decreased productivity among factory workers.

How Industrial Cooling System Works?

Evaporative Cooling Mechanism

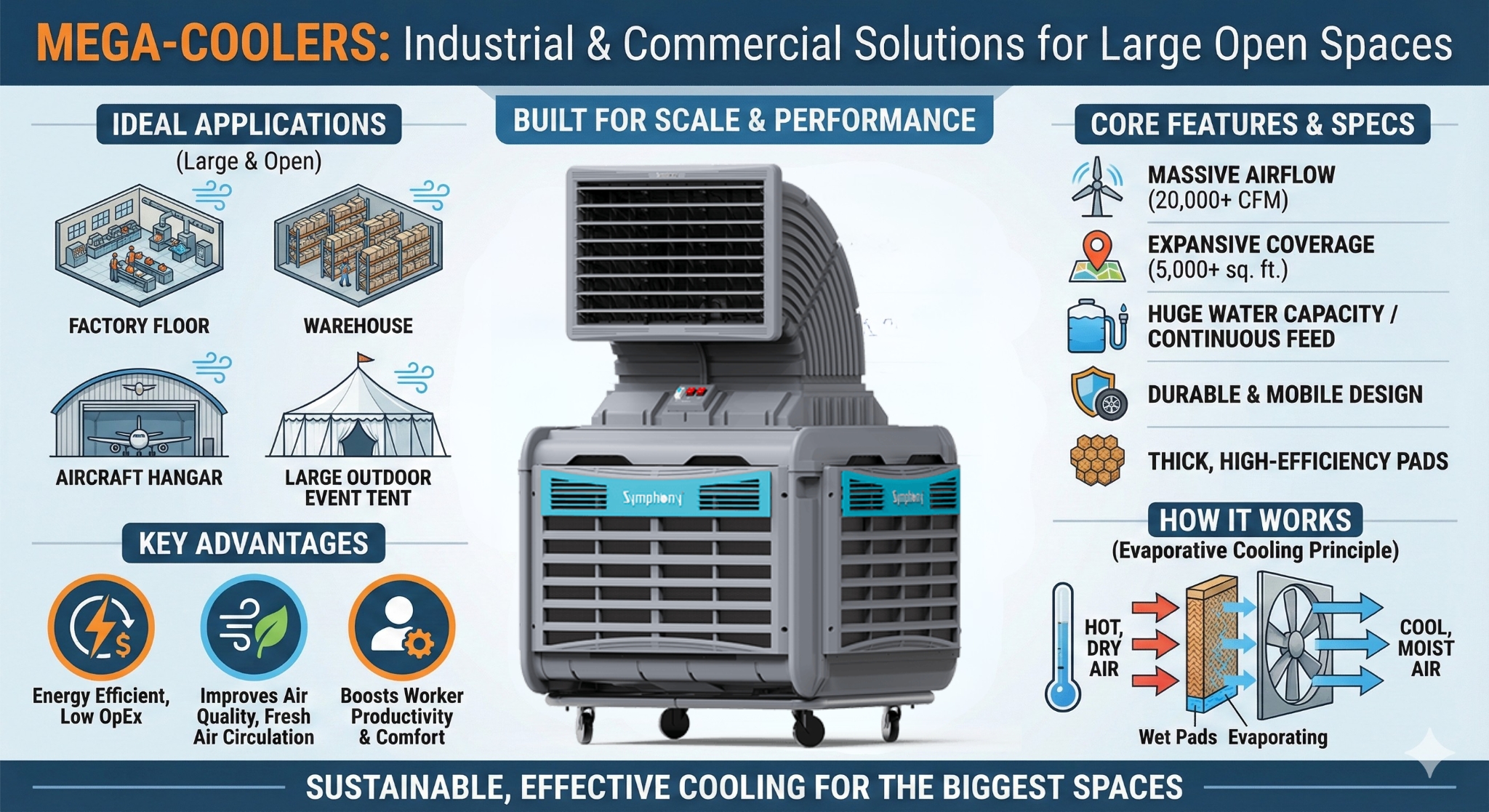

At the heart of these coolers lies a straightforward principle: evaporative air cooling. Just as a breeze feels cooler near a water body due to evaporation, these industrial coolers employ a similar mechanism. Warm air from the factory is drawn into the unit, passing through water-saturated pads. The air cools as water droplets evaporate, and the cooler air is circulated back into the factory.

Components of Industrial Ducting Coolers

Water Pump: Responsible for circulating water through the cooling pads.

Cooling Pads: These pads are designed to absorb water and facilitate the evaporation process.

Fan System: Helps circulate cooled air throughout the factory space.

Control Panel: Allows users to adjust settings and monitor the cooler’s operation.

Benefits of Industrial Cooling System

Cost-Efficient Cooling

One of the most significant advantages of industrial ducting coolers is their cost-effectiveness. They consume considerably less energy than traditional air conditioning systems, which can result in substantial savings on energy bills.

Eco-Friendly Cooling

These industrial cooling systems are environmentally friendly since they use the natural process of water evaporation to cool the air. They don’t rely on harmful refrigerants or contribute to greenhouse gas emissions.

Improved Air Quality

Unlike air conditioners that recirculate indoor air, ducting coolers constantly bring in fresh outdoor air, enhancing indoor air quality by reducing pollutants and odors.

Low Maintenance

Industrial ducting coolers are relatively low-maintenance systems. Regular cleaning and occasional pad replacement are all required to keep them running optimally.

Easy Installation

Integrating these coolers with existing ductwork is a relatively straightforward process that minimizes factory downtime during installation.

Application of Industrial Ducting Coolers for Factories

Manufacturing Facilities

Automotive Plants: Keep assembly lines cool and workers comfortable during production.

Food Processing Units: Maintain hygiene standards while ensuring a comfortable working environment.

Textile Mills: Regulate humidity levels to prevent damage to delicate fabrics and machinery.

Warehouses and Distribution Centres

Temperature Control: Prevent heat-related damage to stored goods.

Employee Comfort: Create a conducive working environment for warehouse staff.

Commercial Spaces

Retail Stores: Ensure a comfortable shopping experience for customers and staff.

Office Buildings: Maintain optimal temperatures for employee productivity and comfort.

Conclusion

Industrial ducting coolers offer a cost-effective, eco-friendly solution for industrial cooling factory environments. By harnessing the power of evaporative cooling equipment, they provide comfortable working conditions while minimizing energy consumption and maintenance requirements.

FAQs About Industrial Ducting Cooling System

Industrial Ducting Cooling System for Factory Operations

Are industrial ducting coolers suitable for all types of factories?

Yes, industrial ducting coolers are designed to be versatile and can be adapted to suit various factory environments.

Do industrial cooling systems work in all climates?

While they are most effective in hot and dry climates, industrial ducting coolers can still provide significant cooling benefits in other climates.

Can industrial coolers with duct replace traditional air conditioning systems entirely?

While they can provide sufficient cooling for many factory environments, in some cases, traditional air conditioning systems may still be necessary, especially in extremely hot climates.

How often do the cooling pads in industrial air coolers need to be replaced?

Cooling pads typically need to be replaced once a year or as needed, depending on usage and environmental conditions.

Are industrial cooling systems noisy?

No, industrial ducting coolers operate quietly, making them suitable for factory environments where noise levels need to be minimized.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.