Table of Contents

A Paradigm Shift in Commercial and Industrial Cooling

The debate between air coolers and HVAC (Heating, Ventilation, and Air Conditioning) systems has persisted for decades, particularly in commercial and industrial applications. While HVAC systems have traditionally been the go-to solution for indoor climate control, the rise of air cooler technology marks a shift toward smarter, more sustainable, and cost-effective solutions. As businesses and industries continue to evolve, the demand for energy-efficient and environmentally responsible cooling methods grows. In India, where temperatures soar, air coolers are emerging as the preferred alternative, especially in commercial and industrial sectors. Let’s look into why air coolers are increasingly being chosen over HVAC systems, exploring industry trends, long-term benefits, and what sets air coolers apart.

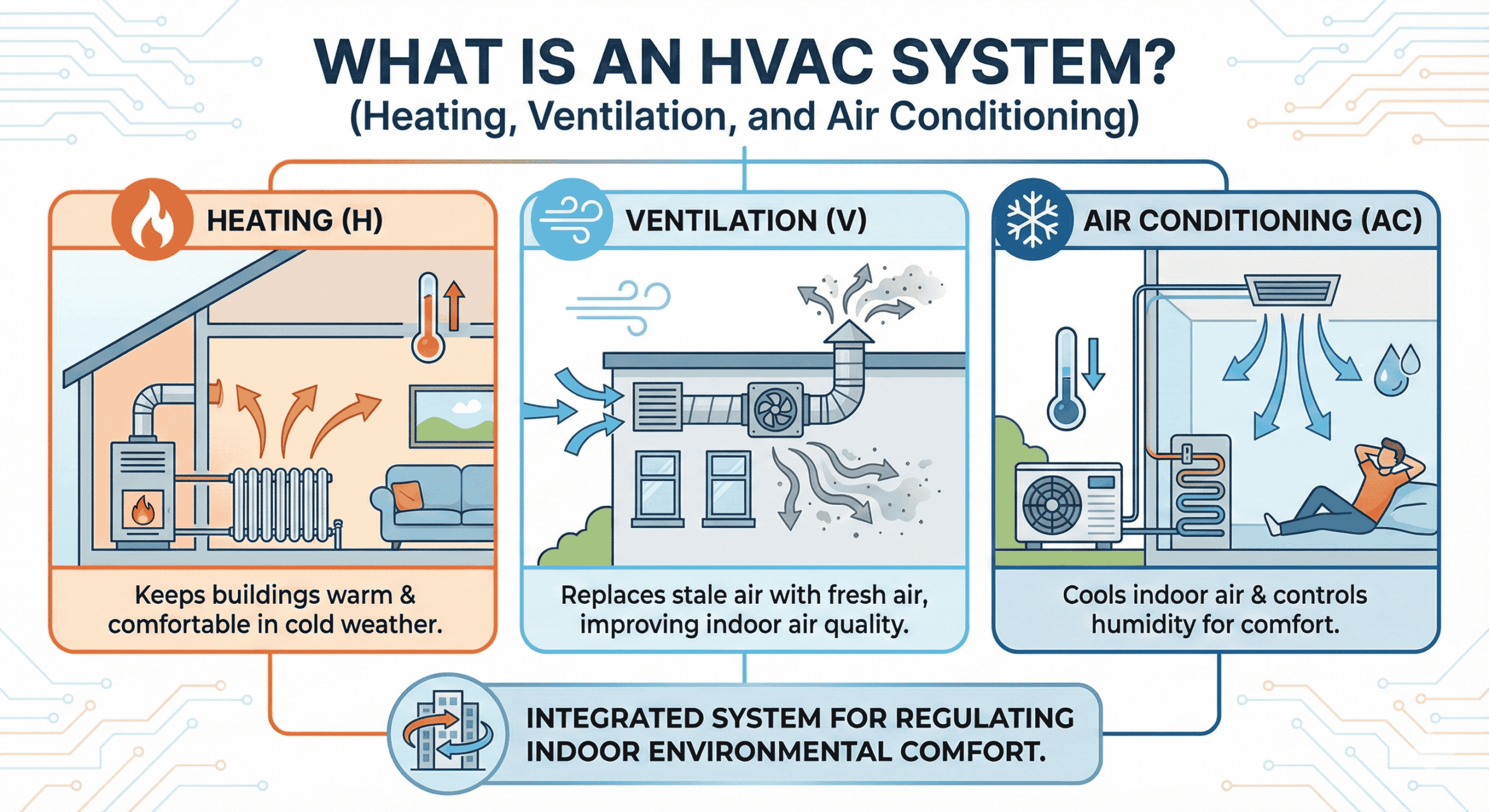

What is HVAC?

HVAC stands for Heating, Ventilation, and Air Conditioning. It is an umbrella term that refers to the different systems used for moving air between indoor and outdoor areas, along with heating and cooling both residential and commercial buildings. They are the systems that keep you warm and cozy in the winter and feeling cool and fresh in the summer. They also are the systems that filter and clean indoor air to keep you healthy and maintain humidity levels at optimal comfort levels.

The purpose of HVAC is to provide an acceptable indoor air quality and thermal comfort. It is a critical component of modern construction, particularly in large office buildings and skyscrapers where natural ventilation is not feasible, and in environments with extreme weather conditions. The design and installation of these systems are integrated into the mechanical engineering and construction of a building.

What is an HVAC System?

An HVAC system is the actual equipment or machinery that delivers the heating, ventilation, and air conditioning. While “HVAC” is the broad category or concept, the “system” refers to the physical unit and its connected parts. This can range from a single window air conditioner unit to a massive centralized system that services a 50-story building.

These systems are designed to control the environment in which they work. This is achieved by controlling the temperature of a room through heating and cooling. It also involves controlling the humidity level in that environment by controlling the movement and distribution of air inside the room. An HVAC system also ensures that the air inside the room is clean by removing dust and other particles through filtration.

What are the Components that make an HVAC System?

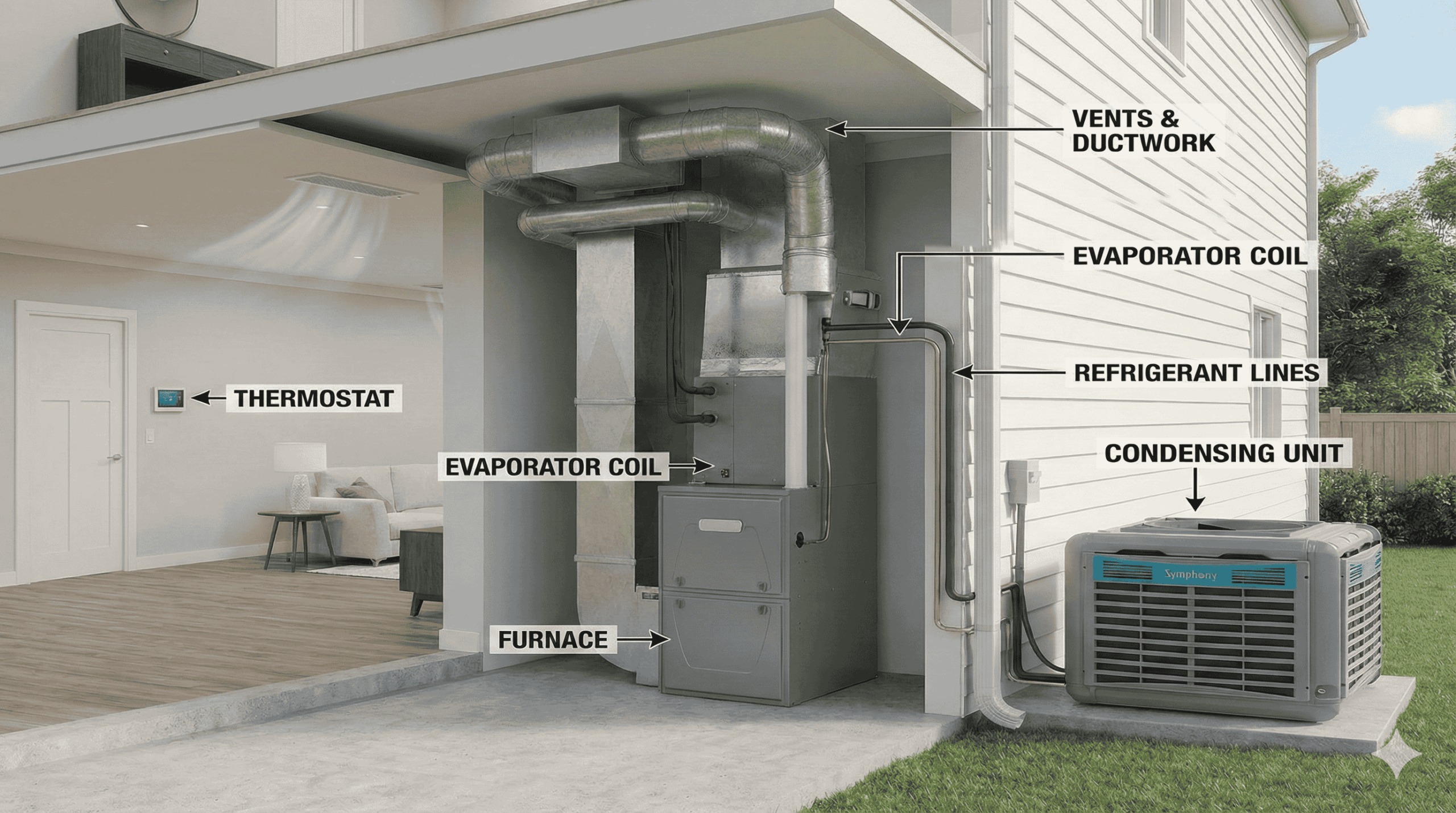

An HVAC system is not just one box; it is an assembly of various components that work together. While the specific parts can vary depending on whether you have a central air system, a furnace, or a heat pump, the fundamental components generally include the following:

The Thermostat This is the most visible part of the system for the average user. The thermostat is the command center where you set your desired temperature. It senses the ambient temperature and signals the rest of the system to turn on or off to maintain the set point.

The Furnace The furnace is the key component for heating. It takes up a large amount of space and is typically located in a basement, attic, or a dedicated utility closet. It uses a fuel source, such as natural gas, oil, or electricity, to heat air which is then distributed throughout the building.

The Evaporator Coil Located inside the indoor unit, the evaporator coil is crucial for cooling. It holds the refrigerant, a fluid that absorbs heat from the indoor air. As warm air passes over the cold coils, the heat is removed from the air, cooling it down.

The Condensing Unit This is usually located outside the building. Its job is to release the heat that was absorbed by the evaporator coil inside. The refrigerant travels from the evaporator coil to the condensing unit, where it is compressed and cooled, releasing the trapped heat into the outdoor air.

The Vents and Ductwork These act as the circulatory system of the HVAC setup. The ducts are the channels through which the heated or cooled air travels to reach different rooms. The vents are the openings where the air enters the room. There are supply vents that blow air out and return vents that pull air back into the system.

The Refrigerant Lines These are the tubes that connect the indoor evaporator coil to the outdoor condensing unit. They carry the refrigerant substance which circulates in a continuous loop, absorbing and releasing heat as it changes states between liquid and gas.

How Does an HVAC System Work?

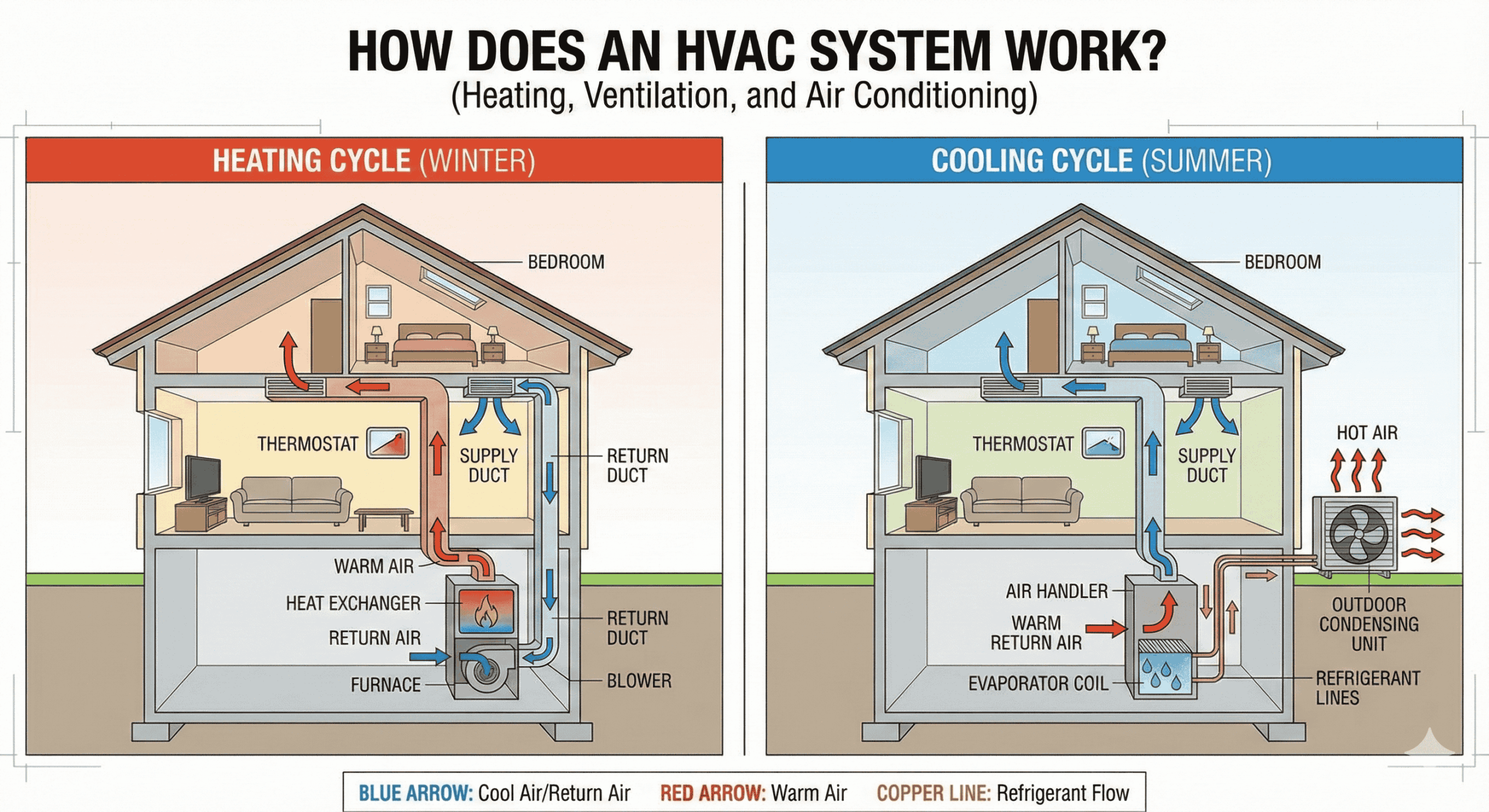

The operation of an HVAC system relies on the principles of thermodynamics, specifically fluid mechanics and heat transfer. The process differs slightly depending on whether the system is heating or cooling, but the core concept of moving air remains the same.

The Cooling Process When you set your thermostat to cool, the system activates. The indoor fan pulls warm air from the house through the return ducts. This air passes over the evaporator coil, which is filled with cold refrigerant. The refrigerant absorbs the heat from the air, turning from a liquid into a gas. The now-cooled air is pushed back through the supply ducts into your rooms. Meanwhile, the gaseous refrigerant travels through the copper lines to the outdoor condensing unit. There, the compressor pressurizes the gas, and the heat is released into the outdoor air as the refrigerant condenses back into a liquid. This liquid returns to the indoor coil to repeat the cycle.

The Heating Process If you have a furnace, the thermostat signals the system to ignite the fuel source (gas or oil) or heat electric coils. This generates heat within a component called a heat exchanger. Air from the home is pulled into the system, passed over the hot heat exchanger, and warmed up. A blower fan then pushes this warm air through the ducts and into your living spaces. If you use a heat pump, the cooling cycle described above is essentially reversed: the system extracts heat from the outside air (even in cold weather) and transfers it indoors.

The Ventilation Process Ventilation is the “V” in HVAC. It involves replacing or exchanging air within a space to provide high indoor air quality. This can happen naturally through windows or mechanically. In mechanical ventilation, the system uses fans to pull in fresh outdoor air and pass it through filters before mixing it with the conditioned air. This prevents the indoor environment from becoming stagnant and helps remove odors and excessive moisture.

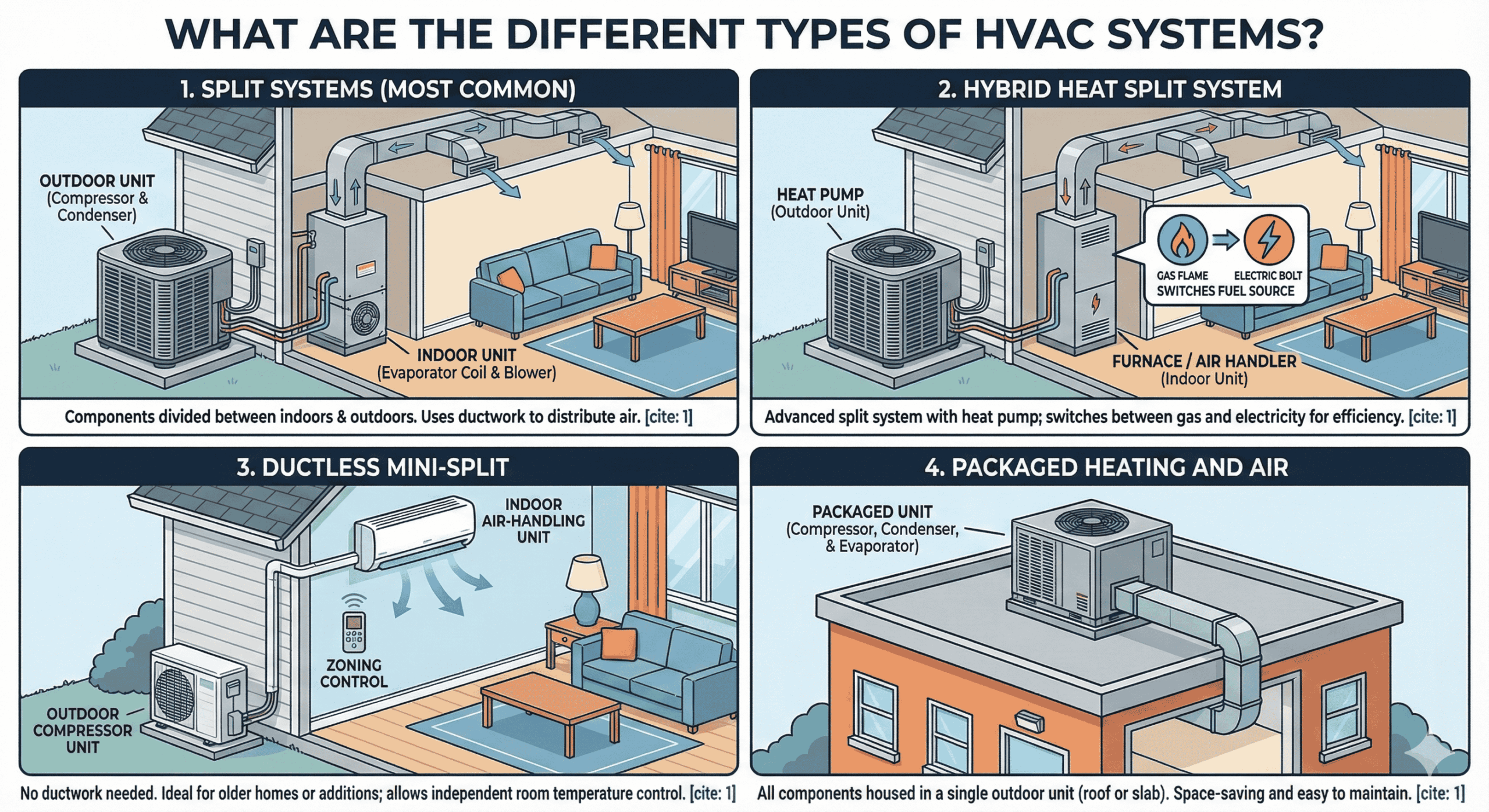

What are the Different Types of HVAC System?

There is no one-size-fits-all solution for HVAC. The type of system installed depends on the age of the building, the climate, and the budget.

Split Systems This is the most common type of system for residential homes. It is called “split” because the components are divided between the indoors and outdoors. It typically consists of an outdoor unit containing the compressor and condenser, and an indoor unit containing the evaporator coil and blower. It uses ductwork to distribute air.

Hybrid Heat Split System This is an advanced version of the classic split system. It includes a heat pump that allows the system to switch between gas power and electricity. This gives homeowners the ability to choose the most efficient fuel source based on the current energy prices and weather conditions, offering significant energy savings.

Ductless Mini-Split As the name suggests, this system does not require ductwork. It involves an outdoor compressor unit and one or more indoor air-handling units. These are mounted directly on the wall of the room they are cooling. They are ideal for older homes where installing ducts is impossible, or for room additions like a garage or sunroom. They allow for zoning, meaning you can control the temperature in each room independently.

Packaged Heating and Air In a packaged system, the compressor, condenser, and evaporator are all housed in a single unit, usually located on a roof or a concrete slab next to the house. These are common in commercial buildings or smaller homes where indoor space is limited. They are efficient and easy to maintain since all parts are in one accessible location.

Air Coolers: A Legacy of Efficient Cooling

The concept of evaporative air cooler is not new. In fact, it’s an age-old technology that has been refined over the years to deliver exceptional cooling performance. Historically, civilizations across the world, including in India, relied on passive cooling techniques such as using water to regulate temperature. Over time, this evolved into modern air coolers that use the same principle-evaporation of water to cool the air.

Global Trend: The Shift towards Sustainable Cooling Solutions

Worldwide, the trend of moving away from energy-intensive air conditioning systems toward more sustainable alternatives is gaining traction. Countries like Australia, Spain, and even parts of the United States have incorporated air coolers in their industrial and commercial spaces due to their energy efficiency and lower environmental footprint. In fact, reports from the International Institute of Refrigeration indicate that evaporative cooling could reduce energy consumption by up to 75% compared to traditional HVAC systems in dry climates.

In India, the adoption of air coolers is particularly suited to the regional climate. The majority of India’s cities experience hot and dry conditions for most of the year, making air coolers the ideal solution. HVAC systems, on the other hand, are inefficient in such environments, consuming significantly higher energy for cooling that is less effective due to the humidity levels.

Air Cooler Vs. HVAC System Initial Cost Breakdown

- Air Coolers have significantly lower upfront costs. These systems are easier and faster to install, requiring no complex ductwork or refrigerants.

- HVAC Systems, on the other hand, require expensive infrastructure (ducts, compressors, etc.) and installation takes more time, with a higher initial investment.

Long-Term Savings vs. Investment

- While HVAC systems might seem like a superior option in terms of cooling capacity, air coolers outperform them over time with lower operational costs and minimal maintenance. The total cost of ownership for air coolers is considerably less, making them a more attractive option for long-term cost savings in commercial and industrial sectors.

Why Air Coolers Stand Strong in India’s Commercial and Industrial Spaces

Energy Efficiency & Cost Savings: The Key Advantage

- Air coolers consume a fraction of the energy that HVAC systems use. A typical air cooler uses about 1/10th of the power compared to an air conditioning system. In commercial and industrial settings, this can translate to substantial cost savings over the long term, especially when cooling large spaces such as warehouses, factories, and distribution centers.

- According to the Bureau of Energy Efficiency (BEE) in India, adopting air coolers instead of HVAC systems can result in up to 70% savings in energy consumption, an attractive proposition for businesses looking to cut operational costs.

- Total Cost of Ownership Analysis: When evaluating the long-term costs of cooling solutions, air coolers consistently outperform HVAC systems. While HVAC installations require expensive ductwork, refrigerants, and frequent maintenance, air coolers are low-maintenance, durable, and easy to operate, with only periodic replacement of cooling pads and simple electrical checks. Considering initial investment, operational energy consumption, and maintenance expenses, air coolers provide a more economical and sustainable solution for commercial and industrial spaces, delivering superior value over the system’s lifetime.

- Energy-Smart Automation Features: Many advanced air coolers feature energy-smart automation, including timers, auto-off modes, and humidity-based fan control. These functions optimize performance, reduce energy wastage, and lower electricity consumption by 15–25% annually in industrial settings. Achieving similar efficiency with HVAC systems requires complex controls and higher energy use, highlighting air coolers’ operational advantages.

Long-Term Operational Benefits

- The longevity of air coolers is another compelling factor. HVAC systems require regular maintenance, including refrigerant refills, filter changes, and high-cost repairs, which adds to the operational costs. In contrast, air coolers are relatively low-maintenance, with only the cooling pads needing periodic replacement, and minimal electrical components to service.

- With fewer moving parts and no complex refrigeration systems, air coolers are less prone to breakdowns, thus ensuring continuous operation with fewer interruptions and lower maintenance costs over time.

Sustainability and Environmental Impact

- The environmental benefits of air coolers are undeniable. While HVAC systems rely on refrigerants that contribute to global warming and ozone layer depletion, air coolers use only water and air, making them a much more eco-friendly choice. As industries across India adopt greener technologies, air coolers align perfectly with the move toward reducing carbon footprints.

- Air coolers also contribute to a healthier environment by ensuring the introduction of fresh, filtered air into indoor spaces. In contrast, HVAC systems often recycle indoor air, which can lead to poor air quality over time.

- Health and Workplace Productivity Benefits: Air coolers play a critical role in enhancing workplace comfort and employee productivity. By supplying fresh, filtered air and reducing heat stress, fatigue, and discomfort, air coolers create a healthier environment compared to HVAC systems, which often recycle indoor air. Research indicates that well-ventilated, cool workspaces can increase worker efficiency by 15–20%. In industrial and commercial settings, this translates into improved morale, safer working conditions, and higher operational performance, benefits that go beyond energy savings and cost efficiency.

- Low Noise Operation for Comfortable Workspaces: Modern air coolers operate at under 55 decibels, ensuring quiet workspaces suitable for offices, retail outlets, and factories. Large HVAC systems often exceed 70 decibels, potentially impacting concentration and workplace efficiency. Low-noise operation improves employee comfort and productivity, further reinforcing the air cooler’s superiority over HVAC systems.

The Evolution of Air Cooler Technology: From Basic to Advance

While air coolers of the past were simple devices with limited cooling capacities, modern air coolers have undergone significant advancements. The integration of Intelligent Airflow Technology (IAT), Automatic Humidity Control, and Smart IoT Features has made air coolers far more efficient and adaptable to the needs of modern industries.

- Intelligent Airflow Technology (IAT): Today’s air coolers are designed with advanced airflow management systems that ensure optimal cooling across large spaces. These systems allow for uniform distribution of cool air, reducing hot spots and improving comfort levels within industrial and commercial environments.

- Smart Features: Modern air coolers come equipped with smart controls, including app-based interfaces, remote monitoring, and automatic settings, which provide convenience and flexibility for businesses managing large cooling systems.

Emerging Features in Air Coolers

- Solar-Powered Air Coolers: Recent innovations in air cooler technology include solar-powered systems that make cooling even more eco-friendly and cost-efficient.

- Self-Cleaning Air Coolers: These units reduce maintenance time and cost by automatically cleaning the cooling pads and filters.

- Advanced Air Filtration Systems: Air coolers now come with integrated filtration systems that help purify the air, improving indoor air quality and creating a healthier environment for employees.

Advanced Intelligent Airflow Technology (IAT)

Modern industrial air coolers feature Intelligent Airflow Technology (IAT), continuously monitoring temperature variations and automatically adjusting fan speed and airflow direction. This ensures uniform cooling, eliminates hot spots, and maintains optimal comfort in large warehouses or factories. Studies indicate that IAT-equipped air coolers can improve energy efficiency by up to 30% compared to conventional air circulation systems, offering a smarter and more cost-effective solution than HVAC systems that require extensive ductwork and higher energy input.

Smart IoT Integration for Remote Control

IoT-enabled air coolers allow facility managers to monitor and adjust cooling parameters remotely via smartphone or web apps. Temperature, humidity, and fan speed can be fine-tuned in real time, while predictive maintenance alerts help prevent downtime. Research shows IoT-enabled air coolers can reduce operational downtime by up to 20%, giving a clear advantage over HVAC systems that often lack cost-effective remote monitoring.

High-Efficiency Evaporative Cooling Pads

Advanced cellulose or honeycomb cooling pads maximize the evaporative effect, delivering rapid temperature reduction even in high-heat industrial spaces. These pads are durable, water-efficient, and easy to replace, consuming 40–50% less water than traditional methods while providing up to 90% cooling efficiency under dry conditions. HVAC systems, relying on energy-intensive compressors and refrigerants, cannot match these eco-friendly and cost-effective advantages.

Air Coolers vs. HVAC Systems: Which is the Right Choice for Businesses?

- Installation and Maintenance: Installing HVAC systems involves complex ductwork, refrigeration units, and significant upfront costs. In contrast, air coolers can be installed much faster and with less disruption to daily operations. Their modular design also allows for scalability, making them ideal for businesses that may need to expand their cooling requirements over time.

- Operating in Extreme Conditions: HVAC systems struggle in extremely hot, dry conditions, where the heat load can overwhelm the air conditioning system, leading to inefficiency. Air coolers, on the other hand, are designed specifically for such conditions, offering a consistent and efficient cooling performance, even in harsh climates.

- Regional Adaptation for India: India’s diverse climate requires cooling solutions that adapt to regional and seasonal variations. In the hot, dry regions of North India, air coolers perform exceptionally well, providing effective cooling with minimal energy use. In more humid areas of South India, high-capacity units or hybrid setups maintain optimal comfort. Even during monsoon periods, adjustments in operation ensure reliable and energy-efficient cooling, making air coolers highly suitable for India’s varied climates-a clear advantage over HVAC systems that often underperform in extreme or fluctuating weather.

- Rapid Cooling for Extreme Heat Zones: Industrial air coolers are engineered to handle extreme heat conditions, capable of lowering ambient temperatures up to 12°C in under 15 minutes. This rapid cooling provides instant comfort for workers and machinery, even in high-heat environments where HVAC systems may struggle or consume excessive energy. Such efficiency makes air coolers particularly suitable for India’s hot and dry industrial regions.

- Low Operating Costs: The total cost of ownership for air coolers is significantly lower than HVAC systems. Over time, the savings in electricity bills, reduced maintenance costs, and lower environmental impact make air coolers the clear choice for many industries, especially in India's cost-sensitive business environment.

Why the Air Cooler Technology is Here to Stay

Air cooler technology’s success in India’s industrial and commercial sectors is not a passing trend. With India’s relentless summers and growing demand for cost-effective, environmentally friendly solutions, air coolers are emerging as the cooling method of choice.

The ability of air coolers to provide energy-efficient, sustainable, and low-maintenance cooling makes them a timeless solution for both commercial and industrial spaces. The shift toward air coolers is not only driven by cost savings but also by their ability to meet the modern-day demands for greener and more responsible business practices.

Modular and Scalable Design

Industrial air coolers are designed for modularity and scalability, allowing businesses to expand cooling capacity by adding units without major infrastructure changes. Case studies show these systems can scale efficiently from 500 sq.m to 5000 sq.m, offering flexible solutions that adapt to growing operational demands-something HVAC systems rarely offer without substantial cost.

Conclusion: Embracing the Future of Cooling Solutions in India

As industries across India look for ways to enhance efficiency while lowering costs and environmental impact, air coolers present a future-proof solution that is adaptable, sustainable, and technologically advanced. For businesses seeking long-term benefits and optimal cooling performance, air coolers offer an unbeatable combination of cost efficiency, sustainability, and superior air quality, all of which are essential for thriving in India’s commercial and industrial landscape.

FAQs: HVAC Systems and Air Coolers Comparison

HVAC Vs. Air Coolers in India’s Commercial & Industrial Sectors

What are EER and SEER, and which is more relevant for commercial HVAC in India?

EER (Energy Efficiency Ratio) measures instantaneous efficiency at a fixed, high outdoor temperature (95°F). SEER (Seasonal Energy Efficiency Ratio) measures average efficiency over a typical cooling season. For India’s highly variable climate, SEER is more relevant as it reflects real-world energy consumption under fluctuating loads, providing a truer picture of annual operating costs.

What are the current industry-standard refrigerants used in commercial HVAC, and what are their environmental challenges?

R-410A (a high Global Warming Potential or GWP HFC) is the current standard but is being phased down under the Kigali Amendment. Alternatives like R-32 (lower GWP HFC) and HFOs (Hydrofluoro-Olefins, very low GWP) are the emerging climate-friendly choices for new systems, directly addressing global warming concerns.

How do Variable Refrigerant Flow (VRF) systems enhance HVAC energy efficiency compared to traditional chillers?

VRF systems allow multiple indoor units to be connected to a single outdoor unit, providing simultaneous heating and cooling in different zones. They modulate refrigerant flow precisely to match the load, dramatically increasing efficiency, especially during part-load operation when the building is not fully occupied or the cooling demand is low.

How does an industrial HVAC system manage the risk of fire and smoke spread through its ductwork?

HVAC systems integrate with fire safety systems using motorized fire dampers and smoke detectors. Upon fire detection, the system automatically shuts down AHUs/fans and closes dampers in affected zones to prevent the spread of smoke and flames, which is a critical safety function in large buildings.

What is HVAC's primary advantage in humidity control, and why can air coolers not match this?

HVAC systems excel at dehumidification. As warm air passes over the cold evaporator coil, the air temperature drops below its dew point, causing water vapor to condense out. Air coolers, conversely, add moisture to the air through evaporation, making them unsuitable where strict humidity control is required. But in advanced air coolers this has been taken care.

For what specific industrial processes is the precise temperature and humidity control of HVAC mandatory?

It is mandatory for cleanrooms (e.g., electronics, pharmaceuticals), data centers, and specific process manufacturing (e.g., printing, textiles) where maintaining parameters within plus/minus 1°C and plus/minus 5% RH is critical for product quality, equipment longevity, or regulatory compliance.

How does the Air Turnover Rate (ACH) of an evaporative cooler compare to a typical VAV HVAC system?

Evaporative coolers operate on an open-loop principle and achieve a very high ACH (often 20 to 30+ changes per hour), prioritizing massive ventilation. HVAC (VAV systems) prioritize thermal control, typically maintaining a lower ACH (often 6 to 10 changes per hour) with high air recirculation.

Which system is better suited for a factory floor where doors and windows must remain open for material handling?

The Air Cooler is unequivocally better. Its open-loop system is designed to continuously flush air out (positive pressure), making it ideal for open, high-ventilation spaces. HVAC relies on a sealed, closed-loop environment and will fail completely if doors or windows are left open, as it cannot handle the resulting heat load.

What is the key advantage of an AHU-based HVAC system in maintaining hygiene for sterile environments?

AHU-based HVAC allows for the seamless integration of multi-stage, high-efficiency filtration (e.g., HEPA filters) and the maintenance of positive pressure (pushing air out of the sterile space), ensuring ultra-clean air that is impossible to achieve with a standard open-loop air cooler.

How does HVAC zoning technology differ from the zone cooling provided by air coolers?

HVAC zoning uses motorized dampers in the ductwork and multiple thermostats (VAV boxes) to deliver precise, different temperatures to sealed rooms simultaneously. Air coolers provide spot or area cooling by directing powerful, cooled airflow into open zones, which only creates comfort locally rather than controlling the overall room temperature.

What is the hidden energy cost of ductwork pressure loss in a large, centralized HVAC system?

Pressure loss (due to friction, elbows, and leakage) forces the main AHU fan to run at a higher speed or be oversized. This significantly increases fan motor energy consumption (OPEX), which can become a major fraction of the total HVAC operational cost over time.

What are the unique maintenance challenges for HVAC systems installed in corrosive coastal or industrial environments?

The primary challenge is condenser coil corrosion (from salt or industrial chemicals) and the deterioration of external casings. This necessitates the use of expensive protective coatings (e.g., corrosion-resistant fins, specialized paints) and more frequent, specialized coil cleaning.

What is the typical annual cost of refrigerant maintenance and replacement for a large commercial HVAC system?

The cost is high due to two factors: the refrigerant itself is expensive (especially phased-down types), and mandatory leak testing and precise recharging require highly skilled, licensed technicians, driving up labor and compliance costs.

What are the main indoor air quality (IAQ) risks associated with recycling air in a sealed HVAC system?

The risks include the build-up of Carbon Dioxide (CO2), Volatile Organic Compounds (VOCs) off-gassing from building materials, and the potential for bio-contaminant (mold/bacteria) growth inside damp coils or ducts if not cleaned properly.

Does the use of air coolers help commercial buildings achieve specific high-level environmental certifications like LEED or GRIHA?

Yes. Air coolers gain crucial points under these standards for water efficiency (low water use per unit of cooling), energy efficiency (low fan power), and Enhanced Indoor Air Quality (IAQ) (due to 100% fresh air intake and high ACH), making them key to achieving higher certification tiers.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.