Table of Contents

Why Evaporative Air Coolers Are Ideal for Industrial Cooling

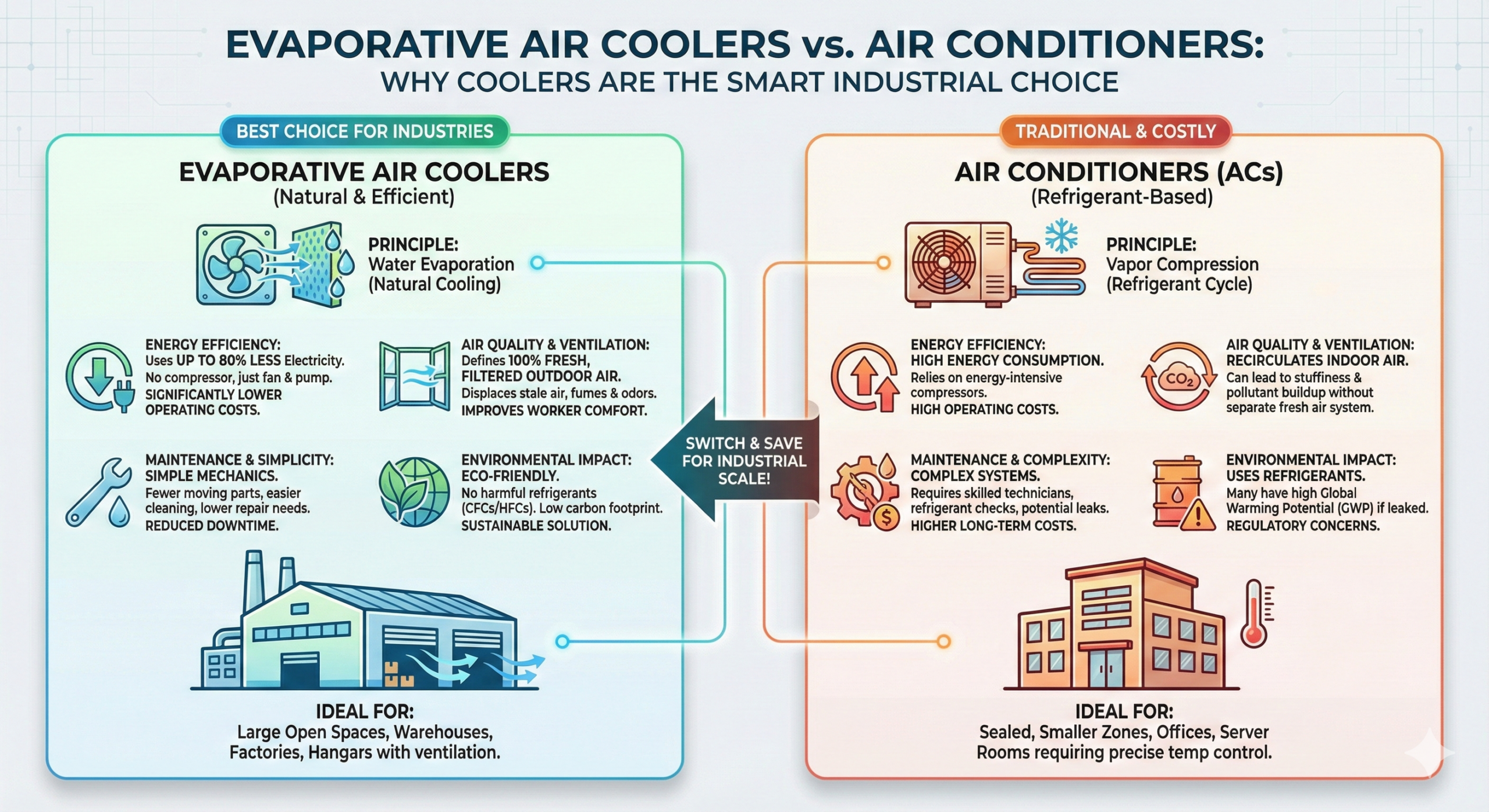

When it comes to cooling solutions for industrial settings, evaporative plastic air coolers offer a range of advantages over ACs. These benefits include energy efficiency, environmental sustainability, cost-effectiveness, and improved air quality. By leveraging the natural cooling process that mimics the breeze over a body of water, evaporative coolers provide a practical and efficient solution for industrial environments. This article explores the various benefits of evaporative cooling equipment in industrial applications.

Evaporative Coolers Energy Efficiency

One of the most significant benefits of industrial evaporative air cooler is their energy efficiency. Unlike ACs, which consume a large amount of electricity to cool the air, evaporative coolers use a simple process of evaporation to achieve cooling.

This process requires far less energy, leading to substantial savings on electricity bills. For industries that operate on a large scale and require extensive cooling, this can translate to significant cost reductions.

Environmentally Friendly Role of Evaporative Air Coolers

Evaporative air coolers are inherently eco-friendly. They operate without the need for harmful refrigerants that are commonly used in air conditioning systems.

These refrigerants, such as chlorofluorocarbons (CFCs) and hydrofluorocarbons (HFCs), contribute to global warming and ozone depletion. By using water as a cooling medium, evaporative coolers avoid these negative environmental impacts. Furthermore, the process of evaporative cooling naturally humidifies the air, which can be beneficial in dry industrial environments.

Cost-Effectiveness of Evaporative Cooling Equipment

The operational cost of evaporative air cooling system is considerably lower than that of traditional HVAC systems. This is primarily because evaporative cooler requires electricity only to power the fan and water pump, resulting in significantly reduced energy consumption.

For industries, this means lower utility bills and a more cost-effective cooling solution. Additionally, the initial investment in evaporative coolers is often lower than that for air conditioning systems, making them a financially prudent choice for many businesses.

Improved Air Quality with Evaporative Coolers

Evaporative cooling equipment contribute to better air quality in industrial settings. As the air passes through the cooling pads, it is filtered, removing dust, pollutants, and other airborne particles. This filtration process ensures that the air circulated within the facility is cleaner and healthier for workers.

Moreover, the increased humidity levels provided by evaporative cooler can help reduce respiratory issues and improve overall comfort for employees, leading to enhanced productivity and well-being.

Easy Maintenance of Evap Air Coolers

Maintenance of evaporative air cooler is straightforward and cost-effective. These systems typically have fewer mechanical components than traditional HVAC systems, resulting in less wear and tear and lower maintenance requirements.

The primary components that may need attention are the water pump and cooling pads, both of which are relatively easy to clean or replace. Regular maintenance ensures that the evaporative cooler operates efficiently and prolongs its lifespan.

Read Our Article: Evaporative Air Cooling: A Noiseless, Eco-Friendly Technology For Religious Places

Reduced CO2 Emissions

Evaporative air coolers have a significantly lower carbon footprint compared to ACs. The minimal energy consumption of evaporative coolers results in reduced CO2 emissions, making them a more sustainable and environmentally responsible choice.

For industries aiming to reduce their carbon footprint and comply with environmental regulations, adopting evaporative cooling technology is a step in the right direction.

Unmatched Versatility and Flexibility with Modern Evaporative Cooling Equipment

Evaporative air cooler is highly versatile and can be used in various industrial settings, including warehouses, factories, workshops, and manufacturing plants.

They are available in different sizes and capacities, allowing businesses to choose a model that best suits their specific cooling needs. Additionally, many evaporative coolers are portable, providing the flexibility to move them to different locations within the facility as needed.

Enhanced Employee Comfort @ Steady Flow of Cool, Fresh Air

Maintaining a comfortable working environment is crucial for employee productivity and morale. Evaporative cooling equipment provides a steady flow of cool, fresh air, creating a more pleasant atmosphere for workers.

The natural cooling process also helps to reduce heat stress, which can be a significant concern in industrial environments, especially during the hot summer months. By improving thermal comfort, evaporative cooler can enhance employee satisfaction and performance.

Evaporative Air Cooler Operates at Reduced Noise Level

Evaporative air cooler operates with fewer mechanical components and do not require a compressor, which is often the primary source of noise in other sustainable cooling systems.

While we do not claim that our coolers provide reduced noise, their design inherently avoids the noise generated by these systems. This can be advantageous in industrial settings where minimizing additional noise can contribute to a more comfortable working environment.

Conclusion

In conclusion, evaporative air cooler provides numerous benefits for industrial applications, including energy efficiency, environmental sustainability, cost-effectiveness, improved air quality, and ease of maintenance.

These advantages make evaporative coolers a compelling choice for businesses seeking efficient and eco-friendly cooling solutions. By adopting evaporative cooling technology, industries can enhance employee comfort, reduce operational costs, and contribute to a greener future.

FAQs About Evaporative Air Coolers for Industry

Evaporative Air Cooler Benefits for Industry

How does an evaporative air cooler work?

Evaporative air coolers work by drawing warm air through water-soaked cooling pads. As the air passes through the pads, the water evaporates, absorbing heat and cooling the air. The cooled air is then circulated throughout the space, providing a refreshing and natural cooling effect.

What are the maintenance requirements for an evaporative air cooler?

Maintenance for an evaporative air cooler typically involves cleaning the cooling pads, checking and replacing the water pump if necessary, and ensuring that the water supply is clean. Regular maintenance helps maintain the efficiency and longevity of the cooler.

Can evaporative air coolers be used in humid climates?

Evaporative air coolers are most effective in dry climates where the humidity is low. In humid climates, their cooling efficiency decreases as the air's capacity to absorb additional moisture is limited. However, they can still provide some cooling and improved air circulation.

Is evaporative cooling equipment energy-efficient?

Yes, evaporative cooling equipment is highly energy-efficient. It uses significantly less electricity than AC because they rely on the natural process of evaporation for cooling. This results in lower energy bills and reduced environmental impact.

What are the environmental benefits of using evaporative air coolers?

Evaporative air coolers have several environmental benefits, including lower energy consumption, reduced CO2 emissions, and the absence of harmful refrigerants. By using water as a cooling medium, they provide a sustainable and eco-friendly alternative to traditional HVAC systems.

What are the different types of evaporative air coolers?

Evaporative air coolers come in several types, including portable coolers, window coolers, ducted coolers, and industrial coolers. Portable coolers are ideal for smaller spaces and can be moved easily. Window coolers are installed in windows and are great for cooling individual rooms. Ducted coolers are suitable for large spaces and can be integrated with ducts for even air distribution. Industrial coolers are designed for large, open spaces such as factories and warehouses, offering high airflow and cooling capacity.

How much does an evaporative cooling unit cost in India?

The cost of an evaporative cooling unit in India varies depending on the type, size, and brand. Portable coolers typically range from ₹5,000 to ₹25,000 for residential models, while industrial coolers can range from ₹30,000 to ₹1,50,000 or more, depending on the cooling capacity. Ducted systems may cost between ₹50,000 to ₹2,00,000. Larger commercial and industrial coolers are more expensive due to their high airflow and energy efficiency. The price also depends on additional features such as smart controls, automatic humidification, and energy-saving technology.

Which is the no. 1 brand in evaporative air coolers?

Symphony Limited is widely recognized as the number one brand in the air cooler category in India and globally. Symphony has the largest market share and are known for pioneering various cooler technologies. With extensive cooler ranges, covering everything from small personal coolers to massive industrial Venti-Cool systems. Symphony’s reputation is built on decades of focus purely on air cooling technology, unlike other brands where coolers are just a small part of a varied appliance portfolio.

Why evaporative cooler is better than AC?

An evaporative cooler is considered "better" than an AC in specific contexts, primarily regarding energy efficiency and fresh air circulation. If you are in a dry, hot climate and want to keep doors or windows open, a cooler is superior as it constantly cycles fresh air rather than recirculating stale indoor air. It consumes about 80-90% less electricity than an air conditioner, offering massive operational savings. However, for sealed rooms or extremely humid coastal areas, an AC might be the preferred choice for temperature control.

Are evaporative air coolers suitable for large commercial & industrial spaces?

The cost savings with evaporative coolers are substantial, primarily driven by reduced electricity consumption. An industrial cooler might use only 10% to 20% of the power required by a comparable air conditioning system to cool the same square footage. Additionally, the initial installation cost (Capex) is significantly lower. Maintenance costs are also minimal since there are no complex compressors or expensive refrigerants to replace, leading to a quick return on investment for businesses.

What are the cost savings of using an evaporative air cooler?

Evaporative air coolers can result in substantial cost savings compared to traditional air conditioning systems. They consume up to 80% less energy, which directly reduces electricity bills. Additionally, they require minimal maintenance and have lower installation costs. In large commercial or industrial settings, these coolers can lower cooling costs significantly, especially in hot, dry climates where their efficiency is maximized. Over time, businesses can save a considerable amount on operational costs, making them a cost-effective cooling solution.

How often should evaporative coolers be maintained?

For optimal performance, evaporative coolers should undergo basic maintenance at least once before the summer season begins and once after it ends. During the active cooling season, it is advisable to clean the cooling pads and drain the water tank monthly to prevent algae build-up and mineral deposits. Commercial units running constantly in dusty industrial environments may require more frequent checks of the filters and pads to ensure the airflow remains strong and the air quality stays high.

Are evaporative air coolers noisy?

Modern evaporative air coolers operate at relatively low noise levels, typically under 55 decibels, which is quieter than many traditional air conditioners. This makes them suitable for environments where noise could disrupt work, such as offices, retail outlets, and factories. Some brands offer low-noise models designed specifically for quiet operation. However, larger industrial coolers may generate more noise due to their higher airflow capacity, but still, their noise levels are often lower compared to large HVAC systems.

Where is the best place to put an evaporative cooler?

For an evaporative cooler to work effectively, it must be placed near a fresh air source. In a home, this means placing the unit in front of an open window or door so it can draw in hot outdoor air. In industrial settings, units are typically installed on the roof or mounted on side walls. Crucially, there must also be an exhaust point (like an open door or window on the opposite side of the room) to allow the humid, warm air to be pushed out, creating a continuous "cross-ventilation" airflow.

What is the cooling capacity of commercial evaporative air coolers?

Commercial evaporative air coolers are much more powerful than home units, with cooling capacities usually measured in CMH (Cubic Meters per Hour) or CFM (Cubic Feet per Minute). A standard commercial unit might deliver between 18,000 to 40,000 CMH of airflow. A single unit of this size can typically cool an area ranging from 2,000 to 3,500 square feet effectively. For larger facilities, multiple units are installed in a modular fashion to cover the entire floor plate.

Where are commercial evaporative air cooling systems typically used?

Commercial evaporative air cooling systems are commonly used in warehouses, factories, showrooms, offices, gymnasiums, shopping malls, and distribution centers. These systems are particularly effective in hot and dry climates, such as those found in North India and parts of West India, where they can provide significant energy savings over traditional air conditioning. They are ideal for spaces that require high airflow, large air volume, and natural ventilation.

What are the installation requirements for a commercial evaporative air cooler?

Installation of a commercial evaporative air cooler requires adequate ventilation, a continuous water supply, and proper drainage for excess water. The cooler should be placed in a location with sufficient airflow, ideally near windows or open spaces. Electrical connections are needed to power the fan and pump, and ducts may be required to distribute cool air evenly across the space. The installation process is typically less invasive and quicker compared to HVAC systems.

What are industrial evaporative air coolers and how do they differ from commercial coolers?

Industrial evaporative air coolers are heavy-duty versions designed for the harshest environments. While commercial coolers might be used in shops or halls, industrial units are built for factories with extreme heat loads. They typically feature more robust bodies (often UV-stabilized plastic to prevent rust), larger cooling pads for higher saturation efficiency, and powerful motors capable of running 24/7. They differ primarily in their durability, air delivery volume, and ability to withstand aggressive industrial conditions compared to lighter commercial models.

What are the main benefits of using industrial evaporative air coolers?

The main benefits of using industrial evaporative air coolers include significant energy savings (up to 80% less energy than traditional HVAC), low maintenance (with easy-to-replace cooling pads and filters), environmentally friendly cooling, and high airflow capacity. They are cost-effective, reduce operational costs, and can cool large, open spaces efficiently. Industrial air coolers are also suitable for extreme heat conditions, offering reliable performance in hot and dry environments.

Are there any safety concerns with industrial air coolers?

Industrial air coolers are generally very safe, but there are standard precautions to observe. Since they use water and electricity together, proper grounding (earthing) is essential to prevent electrical shocks. Regular maintenance is needed to ensure water doesn't leak onto walkways, creating slip hazards. Also, if not cleaned regularly, the water tank can breed bacteria, though this is easily managed with routine draining. Manufacturers like Symphony design their units with sealed electricals to minimize these risks.

Why Symphony Venti-Cool are the best evaporative air cooler available in India?

Symphony Venti-Cool stands out because they use high-grade, UV-stabilized engineering plastic bodies instead of the metal bodies used by local assemblers, making them completely rust-proof and durable. Their units are modular, aesthetically pleasing, and come with standardized spare parts availability, which is rare in the unorganized market. They also feature advanced 'Cool Flow Dispenser' technology for uniform pad wetting, ensuring consistent cooling performance that generic industrial coolers often fail to match over time.

From where to buy evaporative air coolers in India with fast delivery?

To get fast delivery and genuine products, it is best to buy directly through authorized distributors or the company's official corporate sales channels. For Symphony commercial or industrial coolers, visiting the official "Symphony Venti-Cool" website allows you to request a quote or site survey directly. Symphony has a vast network of dealers across major Indian cities, ensuring that stock is locally available for quick installation.

How do evaporative air coolers compare with regular air conditioners?

The fundamental difference lies in the cooling method: air conditioners use chemical refrigerants to recirculate and cool the same indoor air, while coolers use natural water evaporation to cool fresh outdoor air. ACs are effective regardless of humidity but are expensive to run. Coolers are incredibly energy-efficient and eco-friendly but rely on dry ambient air to work best. ACs dry out the air, whereas coolers add moisture, which makes coolers feel more natural and breezy, similar to the cooling sensation of a waterfall.

What features Symphony Venti-Cool Evaporative Air Coolers Offer?

Symphony Venti-Cool models come packed with features designed for industrial efficiency. They offer a completely weather-resistant, non-corrosive plastic body that outlasts metal coolers. They include high-efficiency honeycomb cooling pads on multiple sides for maximum air intake. Other key features include a 'Cool Flow Dispenser' for non-clogging water distribution, dust filters to protect the pads, and compatibility with various controller options for easy operation. Their modular design allows for easy installation and scalability based on the building size.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.