In the world of industrial HVAC, the Air Handling Unit (AHU) is the heart of the system. Traditionally, this meant massive, double-skinned metal boxes housing heavy coils and compressors. But as industries prioritize energy efficiency, hygiene, and agility, the definition of an AHU is changing.

Enter the Symphony Venti-Cool Series – a range of products that has redefined the category. By transforming the traditional metal AHU into a modular, plastic-bodied Evaporative Fresh Air Handling Unit (FAHU), Symphony has created a solution that delivers superior air quality at a fraction of the operational cost.

This article explores what an AHU is, how Symphony Venti-Cool has revolutionized the concept, and provides a step-by-step technical guide for commissioning these modern units.

Table of Contents

What is an Air Handling Unit (AHU)?

Technically, an Air Handling Unit (AHU) is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. Its primary function is to take in outside air, re-condition it (filter and cool it), and distribute it through ductwork.

Read Our Article: Double Skin Air Handling Units: Advantages in Industrial Cooling

The Symphony Venti-Cool Difference

While traditional AHUs rely on refrigerant gases and recirculated stale air, Symphony Venti-Cool systems operate as Fresh Air Handling Systems.

- 100% Fresh Air: Instead of recycling the same indoor air (which spreads germs and fumes), Venti-Cool units pump in 100% fresh, filtered, and cooled oxygen-rich air.

- The Material Shift: Unlike traditional AHUs made of galvanized steel (which rusts and vibrates), Symphony Venti-Cool units are crafted from weather-resistant, UV-stabilized Engineering Plastic. This ensures zero corrosion, longer life, and cleaner air delivery.

Why Modern Industries Are Choosing Symphony Venti-Cool as their Primary AHU

The "Plastic vs. Metal" Advantage

The biggest enemy of a traditional AHU is rust. In coastal areas or chemical plants, a metal AHU body begins to corrode within years.Symphony Venti-Cool units utilize a high-grade polymer body that is:

- Leak-Proof: Rotomolded single-piece tanks prevent the water leakage common in fabricated metal units.

- Insulated: Plastic naturally insulates the water tank from solar heat, unlike metal which conducts heat and lowers cooling efficiency.

Energy Efficiency (The 1/10th Rule)

A traditional Refrigerant AHU consumes massive amounts of power to run compressors. Symphony Venti-Cool relies on the natural thermodynamics of evaporation. A modular Venti-Cool unit can cool the same square footage using roughly 10% of the electricity required by a traditional AC-based AHU. This massive ROI makes it the preferred choice for large-volume spaces like factories and warehouses.

Modular Flexibility

Traditional AHU requires dedicated “AHU Room” and heavy structural reinforcement. Symphony Venti-Cool is designed to be Modular and Plug-and-Play. You can mount these lightweight units on roofs, walls, or window ledges without heavy civil work. If your factory expands, you simply add another module rather than redesigning the entire central plant.

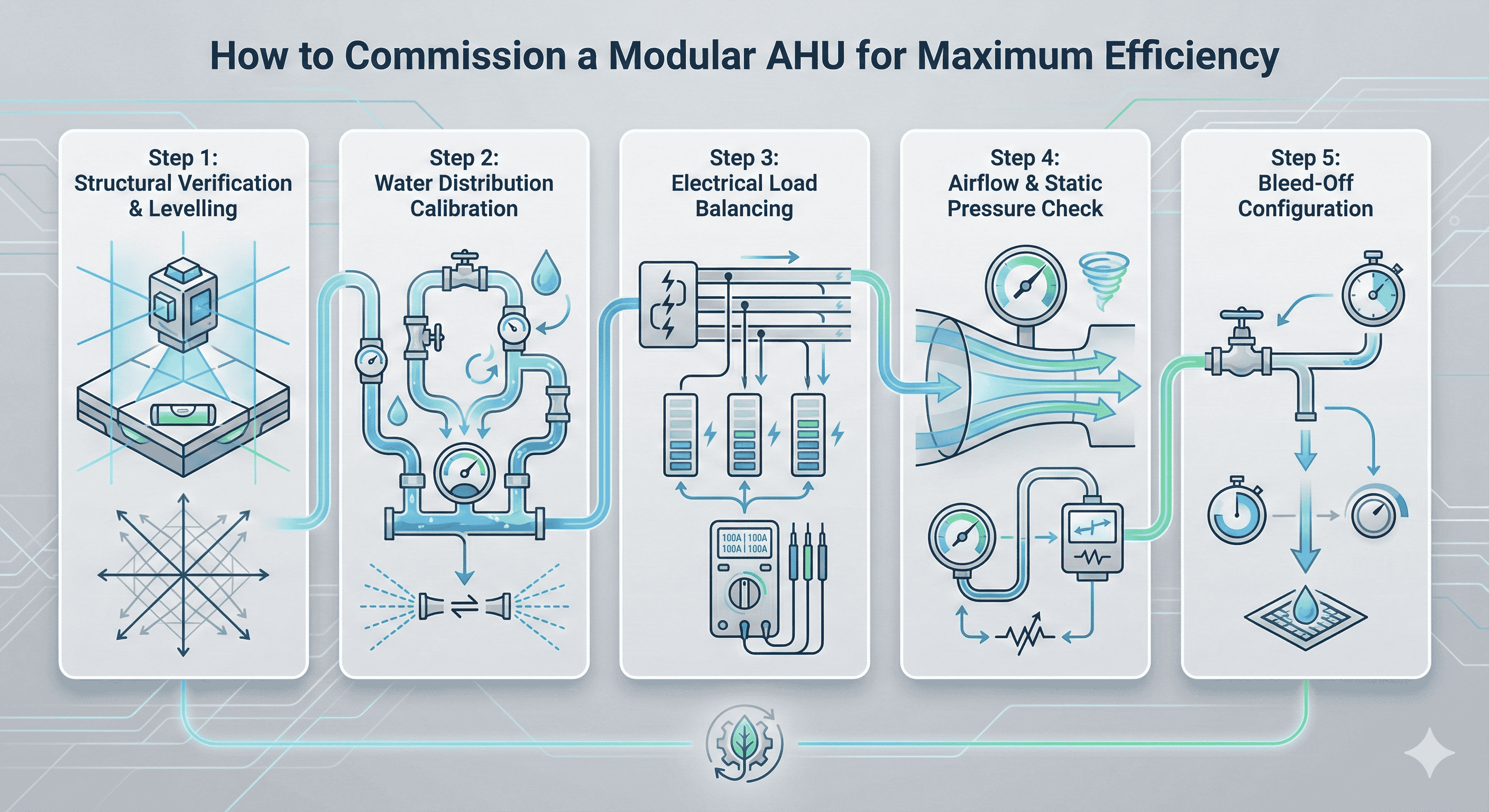

How to Commission a Symphony Venti-Cool Modular AHU for Maximum Efficiency

A step-by-step guide for facility managers to ensure their Symphony Venti-Cool unit is installed and calibrated for peak airflow and cooling performance.

Step 1: Structural Verification and Levelling

Before turning the unit on, ensure the mounting stand is rigid. Place a Spirit Level on the base of the Venti-Cool unit. A perfectly level unit is critical; if it tilts, the water distribution over the honeycomb pads will be uneven, leading to dry spots and reduced cooling. (Tip: Ensure the unit has at least 3 feet of clearance on all sides for fresh air intake.)

Step 2: Water Distribution Calibration

Turn on the “Pump” mode without the Fan. Open the side panels and visually inspect the water distribution headers. The water should flow uniformly over the entire width of the Honeycomb Pads. If you see dry streaks, adjust the flow valve or clean the distribution tubes to ensure 100% pad saturation.

Step 3: Electrical Load Balancing

Start the main blower fan. Use an Ammeter to check the current (Amps) drawn by the motor. Compare this against the “Rated Current” on the Symphony Venti-Cool nameplate. If the amp draw is too high, check the belt tension or duct static pressure. Running within the rated amps ensures the motor lasts for years.

Step 4: Airflow & Static Pressure Check

Once the system is running, use an Anemometer at the duct grill to measure the air velocity. Ensure the static pressure in the ducting matches the Venti-Cool unit’s specifications (e.g., if the unit is rated for 150 Pa, your duct design should not exceed this). This ensures the air reaches the furthest end of the room.

Step 5: Bleed-Off Configuration

Locate the Bleed-Off valve. Adjust it to allow a small, continuous trickle of water to drain out during operation. This step is vital – it prevents salt buildup (TDS) in the tank, keeping the pads clean and the air fresh.

Technical FAQs: Symphony Venti-Cool vs. Traditional AHUs

Technical FAQs: Symphony Venti-Cool vs. Traditional AHUs

Can Symphony Venti-Cool replace my existing Central AHU?

For large industrial floors, warehouses, and semi-open commercial areas, yes. It can replace standard Air Handler Unit’s to provide "Spot Cooling" or "Space Cooling" at a fraction of the cost. For sealed clean rooms requiring strict humidity control (e.g., < 40% RH), Venti-Cool is often used as a Fresh Air Pre-Cooler in hybrid systems.

How does the plastic body handle outdoor UV exposure?

Symphony uses UV-Stabilized Engineering Plastic. Unlike cheap plastics that crack in the sun, Venti-Cool bodies are chemically engineered to withstand direct sunlight and extreme temperatures (up to 50°C+) without degrading or becoming brittle.

Is the cooling media distinct from standard coolers?

Yes. Symphony uses high-efficiency Cellulose Honeycomb Pads. These pads are chemically treated to resist rotting and provide a larger surface area for evaporation compared to the wood-wool pads often found in locally fabricated metal kits.

Can Symphony Venti-Cool be used as a standalone Air Handling Unit (AHU) for factories?

Yes. For large-volume industrial spaces like textile mills, auto-ancillaries, and warehouses, Symphony Venti-Cool is designed to function as a standalone Evaporative AHU. It effectively replaces traditional metal AHUs by delivering high volumes of 100% fresh, filtered cool air without the need for energy-hungry compressors.

How does Symphony Venti-Cool control humidity in high-humidity regions?

While evaporative cooling naturally adds moisture, Symphony Venti-Cool systems are designed for "Once-Through" ventilation. By maintaining high air velocity and ensuring proper exhaust (Air Changes Per Hour), the system prevents humidity build-up. In coastal areas, they act as effective Fresh Air Ventilation Systems, constantly flushing out stagnant, humid indoor air.

What is the maximum static pressure a Symphony Venti-Cool unit can handle?

The Venti-Cool series is engineered with powerful axial and centrifugal fan options. They can handle significant duct static pressure (typically ranging from 150 Pa to 400 Pa depending on the model like VC 20U or VC 25U), allowing for extensive ducting networks to reach deep inside the factory floor.

How often do the Honeycomb Pads need replacing in a Symphony industrial cooler?

With proper maintenance (using the bleed-off valve and regular cleaning), the high-efficiency cellulose honeycomb pads in Symphony Venti-Cool units typically last 3 to 5 years. This is significantly longer than wood-wool pads used in local fabricated coolers, which often rot within a single season.

Does the Symphony Venti-Cool system require a dedicated Air Handling Unit Room?

No. Unlike massive metal AHUs that require a reinforced concrete room, Symphony Venti-Cool units are modular and lightweight. They are designed for flexibility and can be installed directly on roofs, wall brackets, or window ledges, freeing up valuable floor space inside your facility.

How much electricity does a Symphony Venti-Cool save compared to an AC AHU?

The savings are substantial. A Symphony Venti-Cool system typically consumes 1/10th of the electricity of a refrigerated Air Handling Unit for the same cooling area. For a 10,000 sq. ft. factory, this translates to saving lakhs of rupees annually in operational expenses (OPEX).

What kind of warranty and service support does Symphony offer for industrial projects?

Symphony is a global leader with a pan-India service network. Unlike local fabricators who offer no after-sales support, Symphony Venti-Cool projects typically come with professional AMC (Annual Maintenance Contract) options and warranty backing, ensuring your industrial cooling system has maximum uptime.

Conclusion

The definition of the Air Handling Unit has evolved. It is no longer just about moving air; it is about moving air intelligently.

Symphony Venti-Cool represents the future of this technology. By combining the power of an industrial AHU with the efficiency of evaporative cooling and the durability of high-grade engineering plastic, Symphony offers a solution that is robust, eco-friendly, and financially smart. For industries looking to upgrade their infrastructure, the switch to Venti-Cool is not just an option – it is the competitive advantage.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.