Steel manufacturing is an energy-intensive process that generates a considerable amount of heat, making it critical for steel plants to implement effective cooling solutions. In the bustling steel manufacturing hub of Jamshedpur, Tata Steel stands as a testament to cutting-edge industrial cooling solutions that not only enhance operational efficiency but also maintain the safety and productivity of their workforce. This case study delves into how Tata Steel adopted innovative industrial cooling systems to address their specific cooling needs, optimize production and ensure optimal environmental conditions.

Table of Contents

How Do Industrial Cooling Units Enhance Steel Manufacturing Efficiency?

Steel production involves numerous stages, such as the smelting of iron ore, the rolling of hot metal and the tempering process, all of which generate significant amounts of heat. Industrial cooling units play a crucial role in regulating temperature across different sections of a steel manufacturing plant. By providing a consistent cooling effect, these units help in preventing heat stress on both machinery and workers.

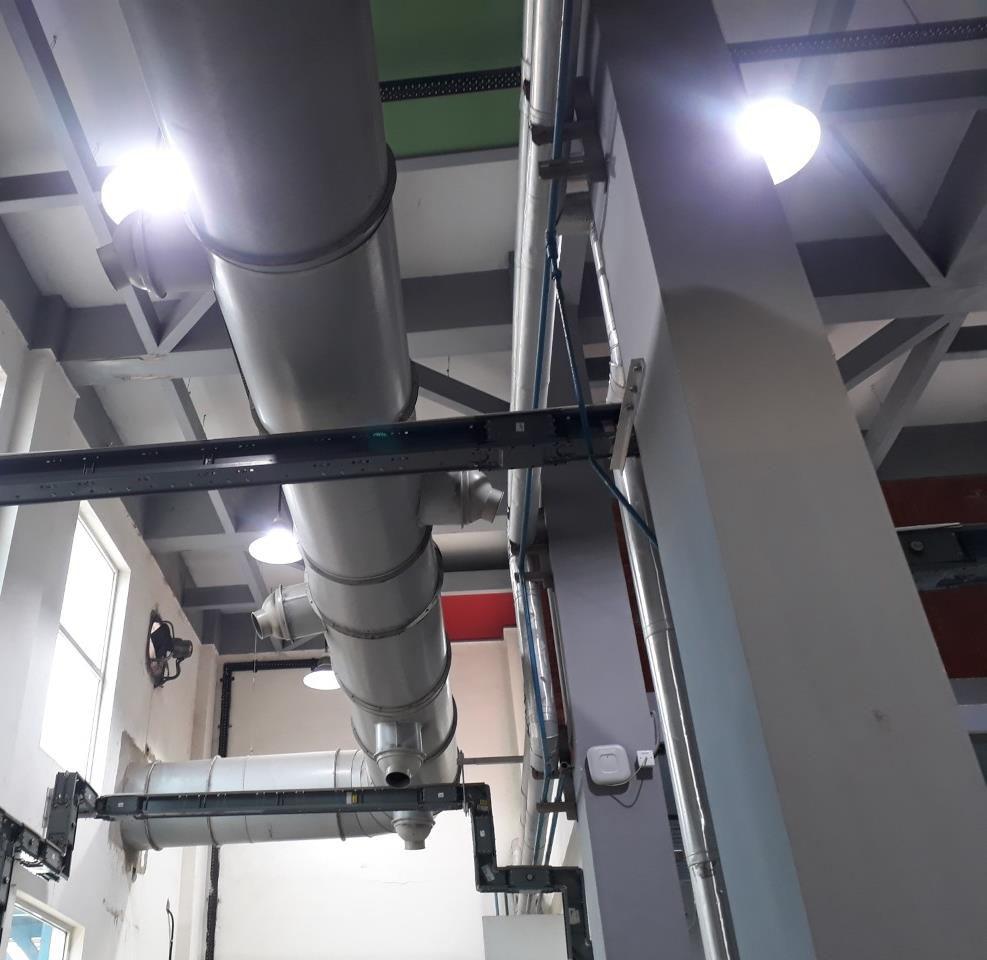

In Tata Steel’s Jamshedpur plant, industrial cooling units are strategically placed in areas where heat buildup is most critical, such as the welding lab and production lines. The implementation of SPS 45 side discharge units, for instance, provides excellent cooling coverage while being energy-efficient, which contributes to reduced downtime and increased productivity. These units are equipped with high-quality cooling pads that facilitate superior heat absorption, ensuring consistent and efficient cooling. Visit – https://symphonyventicool.com/installation/public/upload/document/1696244520_doc_pdf.pdf

When Should Steel Plants Adopt Industrial Air Coolers?

For steel manufacturers in Jamshedpur or other similar regions, the decision to adopt industrial air coolers should be made when there is a need to manage large-scale heat emissions effectively. Whether it’s during regular operations or peak production periods, a well-designed cooling system can significantly improve working conditions.

Plants like Tata Steel in Jamshedpur often require cooling solutions in specific areas, such as welding labs or large production halls, where temperatures can rise unpredictably. In such cases, adopting advanced industrial cooling systems, such as the SPS 45 series, becomes essential for maintaining efficiency. These systems are designed for continuous use and are particularly effective in regions where the external temperature may also influence the internal environment, adding to the cooling challenge.

Where Do Industrial Coolers Fit in Steel Manufacturing Plants?

Industrial air coolers are versatile systems that can be used across various sections of a steel plant, from cooling areas in workshops to maintaining climate-controlled environments in laboratories. For instance, Tata Steel’s welding lab in Jamshedpur utilizes SPS 45 side discharge units to keep temperatures within optimal ranges. This particular setup is ideal for spaces where direct exposure to excessive heat could affect both the workers and the quality of the manufactured products.

The flexibility of industrial air coolers like the SPS 45 makes them suitable for different plant areas, including:

- Welding Stations: These areas generate intense heat and fumes, making it necessary to install cooling systems that can handle such extreme conditions.

- Machinery Halls: High-powered machines that run continuously generate substantial heat, making the cooling of the plant floor critical to avoid machine breakdowns.

- Large Production Areas: In steel manufacturing plants, vast spaces are dedicated to metal shaping, forging and rolling, all of which require consistent temperature regulation.

Why Are SPS 45 Side Discharge Units Ideal for Steel Manufacturing in Jamshedpur?

The SPS 45 side discharge unit stands out as one of the best industrial coolers for large-scale steel manufacturing applications. Tata Steel’s choice of this unit reflects its advanced technology and ability to provide superior cooling over large areas. The unit’s design ensures it can handle the specific demands of steel plants, where cooling needs can fluctuate based on operational intensity.

The key points of the SPS 45 side discharge unit include:

- Efficient Air Distribution: The side discharge mechanism ensures uniform air distribution, which helps in maintaining consistent temperatures in large spaces.

- Durability: Made with high-quality materials, these units are designed to withstand harsh industrial environments, providing reliable long-term performance.

- Energy Efficiency: With high cooling capacity and low energy consumption, SPS 45 units are cost-effective solutions for steel manufacturing facilities.

- Compact Design: Despite their powerful cooling performance, these units are compact and easy to install, saving space within the facility.

What Are the Key Considerations in Selecting Industrial Air Coolers?

When selecting the best industrial air cooler for a steel manufacturing plant, several factors need to be taken into account to ensure optimal performance:

- Cooling Capacity: The cooling system must be able to handle the volume of heat generated in the plant without overburdening the system. It’s important to select air coolers that can meet the specific cooling needs of the plant, based on size, operational intensity and the nature of heat generation.

- Energy Efficiency: Energy costs are a major concern for steel manufacturers. Choosing industrial air coolers with energy-saving features can help reduce operational costs.

- Environmental Adaptability: Air coolers must be able to operate effectively within the plant’s environmental conditions. Factors like ambient temperature, humidity levels and airflow play significant roles in cooling efficiency.

- Maintenance Requirements: Steel plants often operate around the clock and any downtime due to maintenance can lead to significant productivity losses. Selecting coolers that require minimal maintenance while providing consistent performance is crucial for maintaining operational continuity.

Conclusion

Industrial cooling solutions are indispensable for steel manufacturing facilities, especially in high-temperature environments like those found in Jamshedpur. By adopting advanced air coolers like the SPS 45, Tata Steel has been able to create a comfortable and safe working environment for its workforce while improving overall operational efficiency. These cooling systems not only help in controlling temperatures but also in reducing maintenance costs and ensuring the longevity of machinery.

As steel manufacturing continues to evolve, the need for innovative cooling solutions will only grow and the case of Tata Steel in Jamshedpur serves as an exemplary model for other plants aiming to optimize its cooling processes. Implementing the right industrial cooling units can significantly enhance plant productivity, reduce downtime and ensure a sustainable, efficient manufacturing process.

Maulik Solanki is a seasoned B2B Product Marketing professional specializing in Industrial and Commercial Coolers in the LSV (Large Space Venticooling) segment. With 13+ years of experience, he drives brand building and audience engagement for Symphony’s LSV solutions through integrated offline and online strategies. Backed by an MBA in Marketing and earlier experience as a Regional Marketing Manager in banking, Maulik brings strong skills in sales, advertising, and events. He enjoys exploring new marketing ideas and cooling technologies and writes to help readers understand Symphony’s offerings.

Sourav Biswas is a senior marketing leader heading the LSV (Large Space Venticooling – B2B) marketing function at Symphony Limited. He shapes the brand’s strategic narrative, strengthens market leadership, and ensures excellence across all B2B cooling solutions. With deep expertise in Strategic Marketing, Brand Management, Advertising, and PR, he reviews content with analytical precision and alignment to Symphony’s vision. Passionate about mentoring and tracking B2B trends, Sourav ensures every content piece reflects accuracy, relevance, and strategic depth.